Solidworks Sheet Metal Gap Distance

In the graphics area select the edges where you want to add a hem.

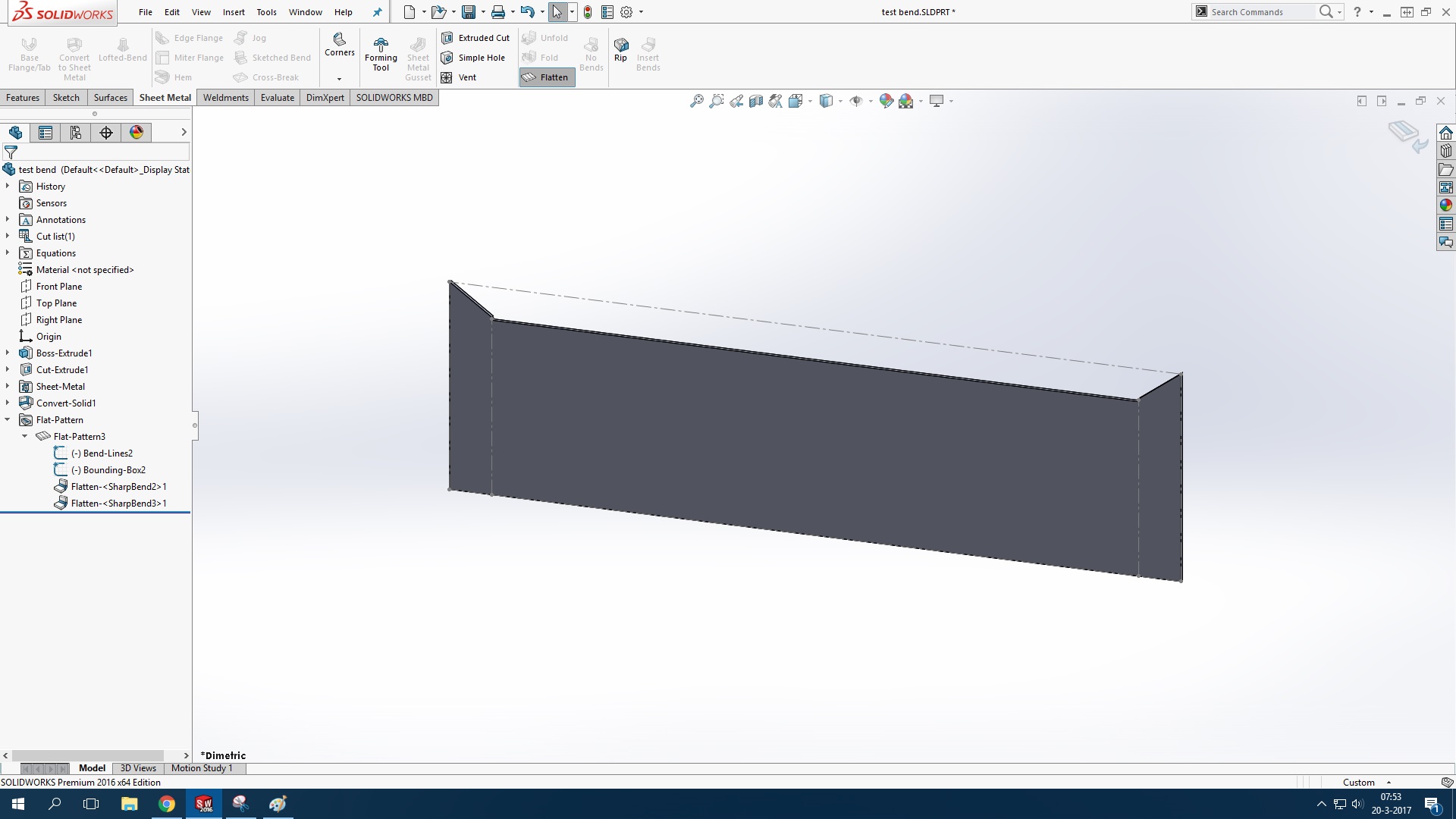

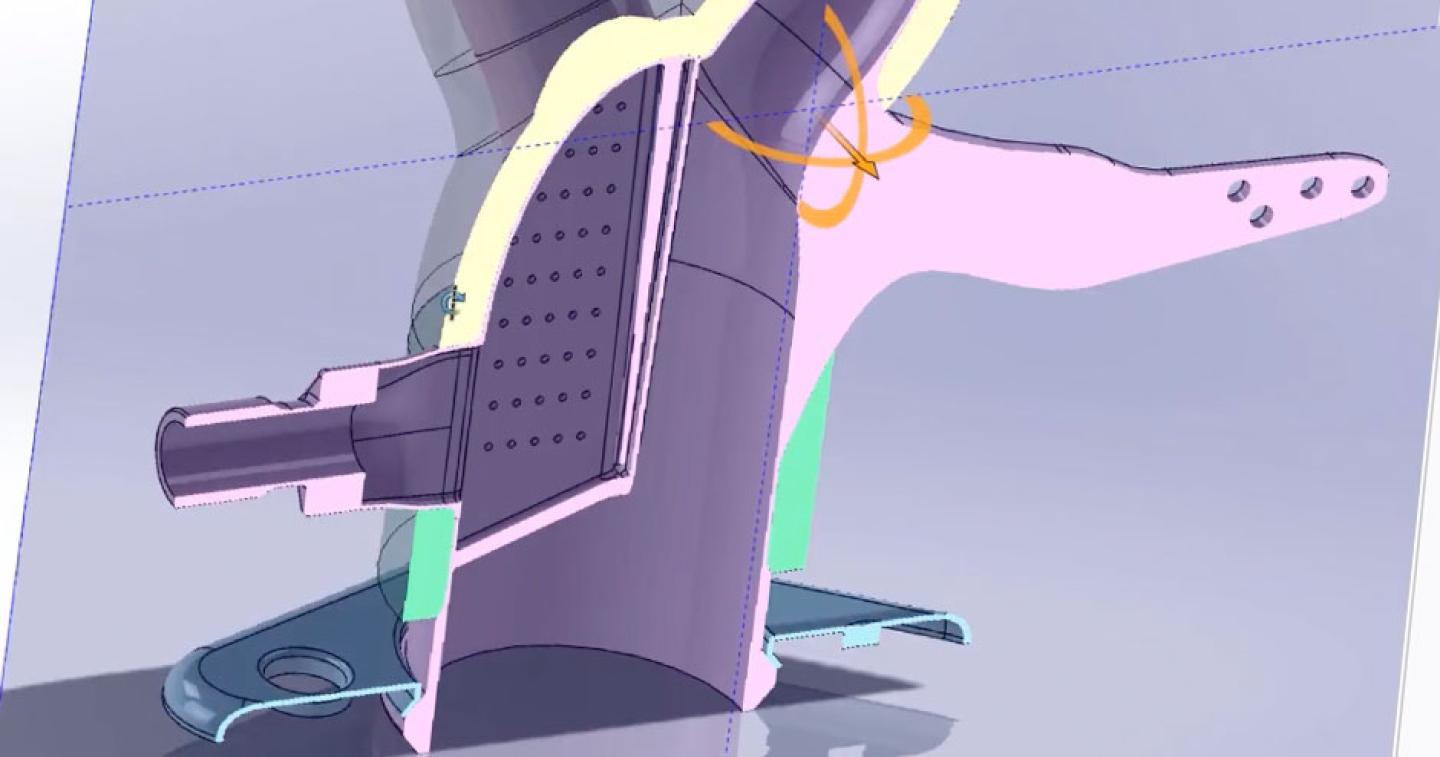

Solidworks sheet metal gap distance. However in some circumstances when the design requires certain types of geometry you can use non sheet metal feature tools then insert bends or convert the part to sheet metal. You might also like. 1 solidworks tutorial for be. Start a new inch part and create a new sketch on the front plane.

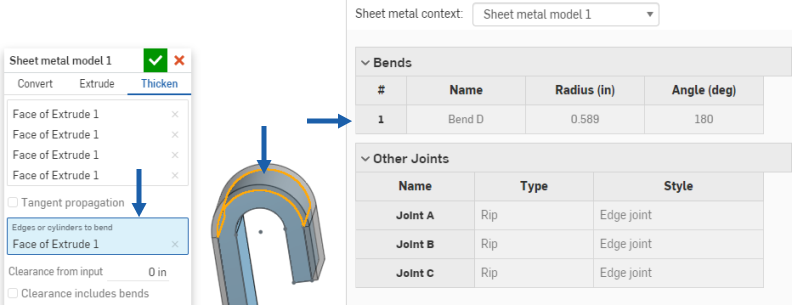

Sheet metal gap distance. Set a value when use default radius and use gauge table are cleared. Only available if a sheet metal gauge table has been selected for the part select or clear. How to use solidworks miter flange solidworks sheet metal tutorial 2 sheet metal miter flange is also like edge flange helps to add one or more flanges on base flange sheet metal part.

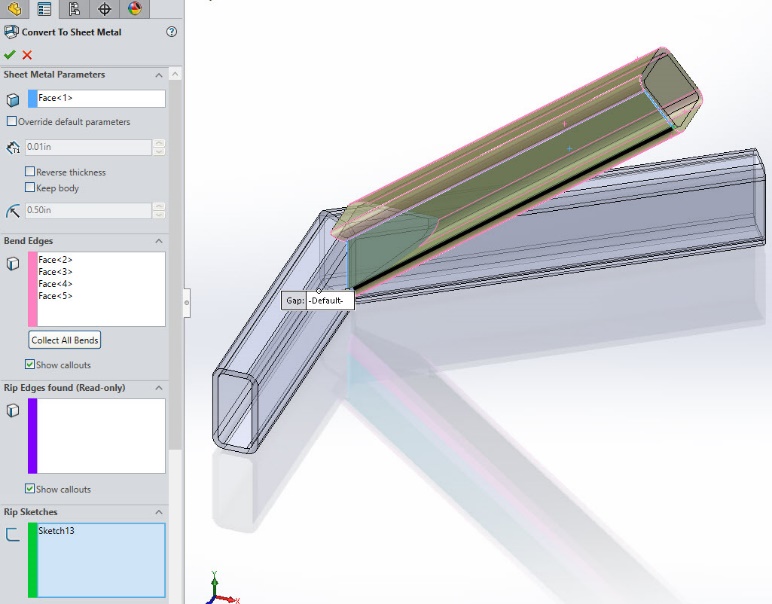

In the propertymanager under edges. Constrain the geometry and dimension as shown. Close multiple corners simultaneously by selecting the faces for all of the corners that you want to close. The rectangular geometry on the right side of the sketch is used to create and center a gap in the sketch geometry.

Like show 0 likes 0. Select material inside or bend outside to specify where to add the material. Like show 0 likes 0. We will learn sheet metal basic features like base flange edge flange sketched bend and extruded cut in solidworks sheet metal.

Finish sketch and exit sketch. If so where is this located. Now let s use solidworks to create a sheet metal transition. Adjust the gap distance.

Sheet metal gap distance. Click edit hem width to edit the sketch of the profile. How to implement these formulae in solidworks so they are smart models. The closed corner feature adds material between sheet metal features and includes the following capabilities.

Discussion created by 1 f44ghu on nov 4 2008. There are specific sheet metal features you can use to create sheet metal bodies quickly. Question asked by 1 f44ghu on nov 4 2008 latest reply on nov 7 2008 by angela crawford. Is there a default location for the gap distance measurment.

Miter flange is slightly different from edge flange because it needs a sketch profile of lines or arcs. The selected edges appear in edges.