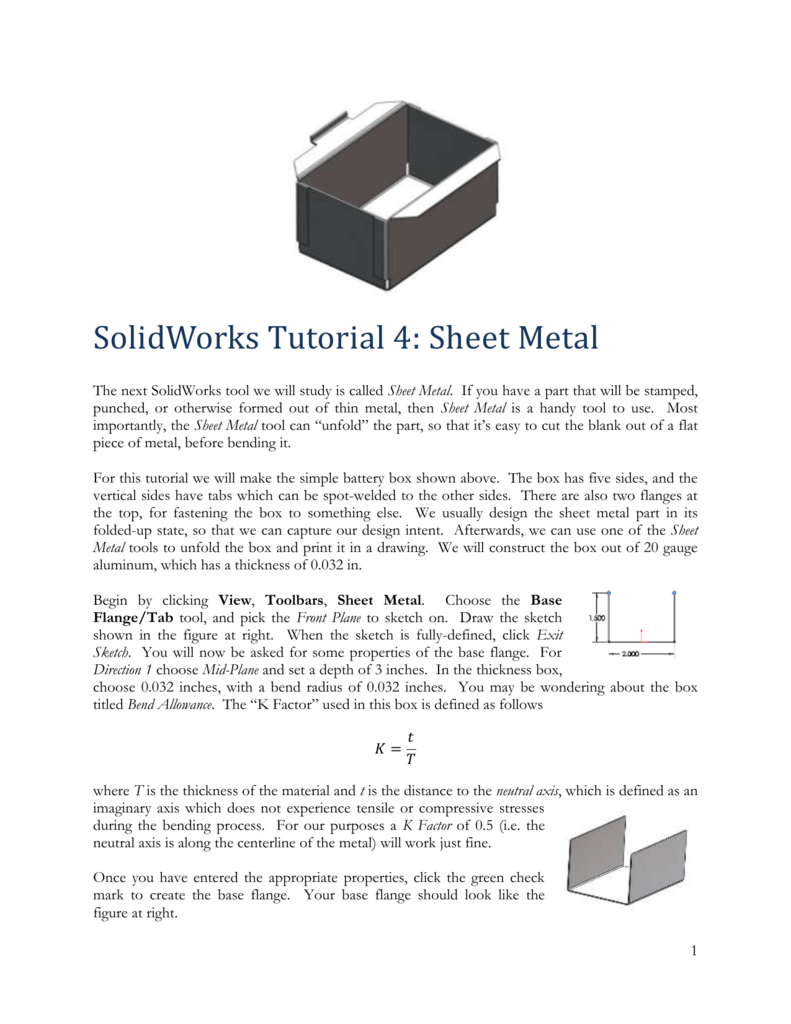

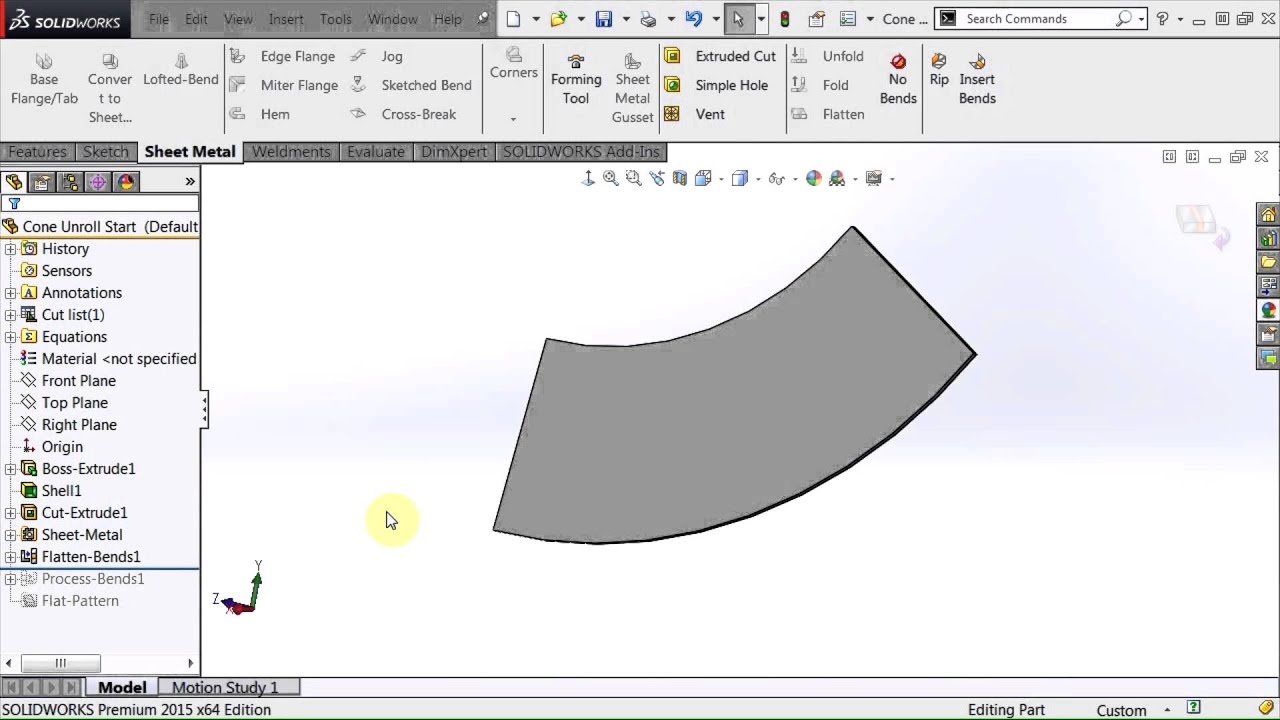

Solidworks Sheet Metal Getting Blank Size

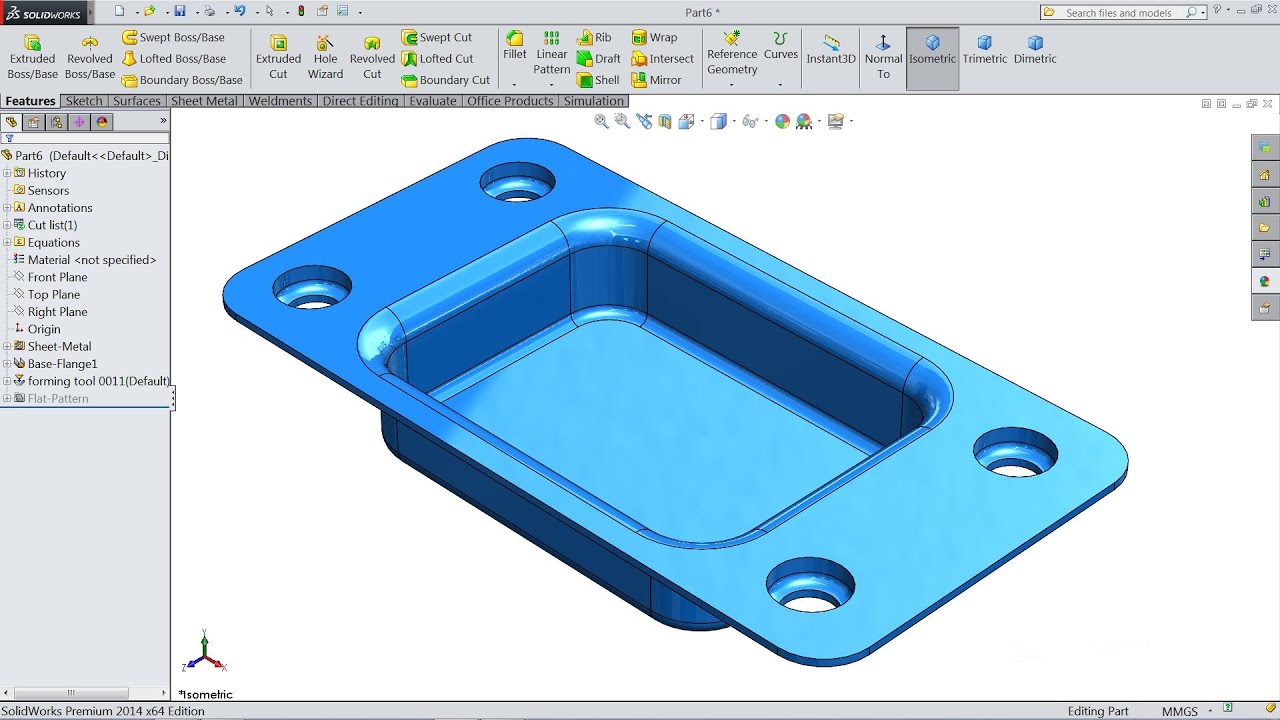

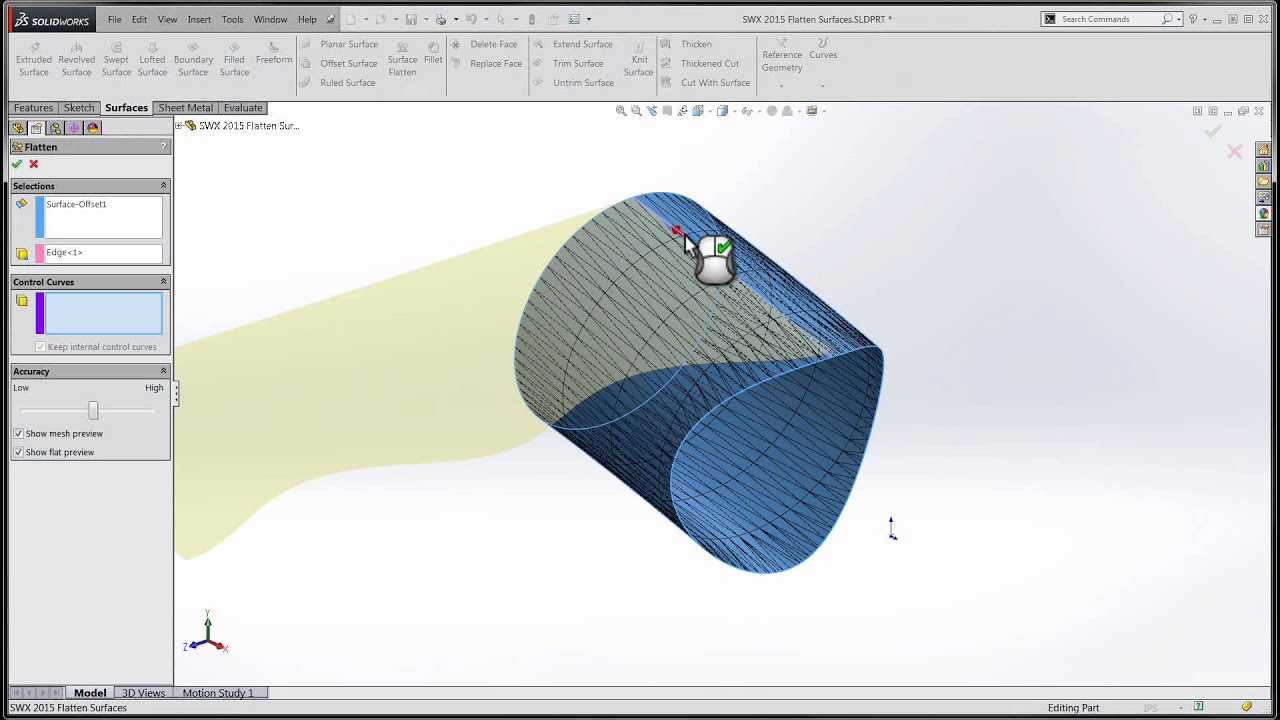

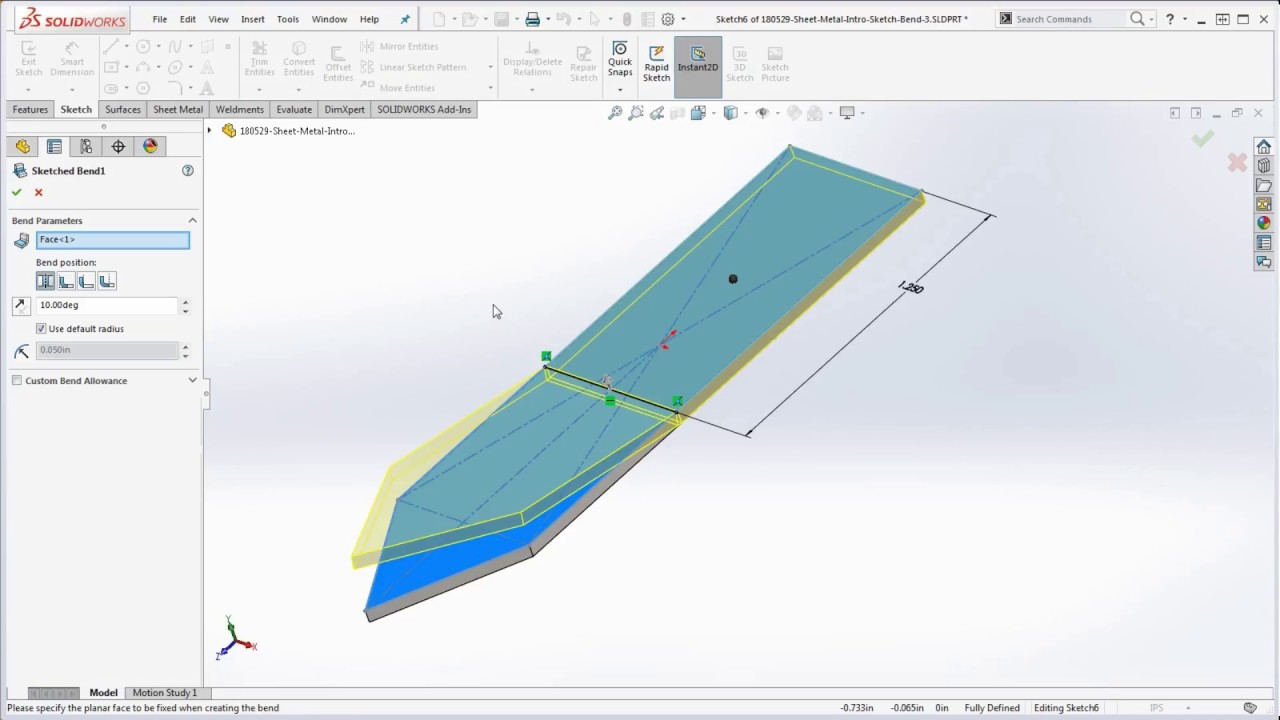

We will learn sheet metal basic features like base flange edge flange sketched bend and extruded cut in solidworks sheet metal.

Solidworks sheet metal getting blank size. Sets an option to define the calculation method. There are specific sheet metal features you can use to create sheet metal bodies quickly. Google solidworks sheet metal stuff. Almost all air bending.

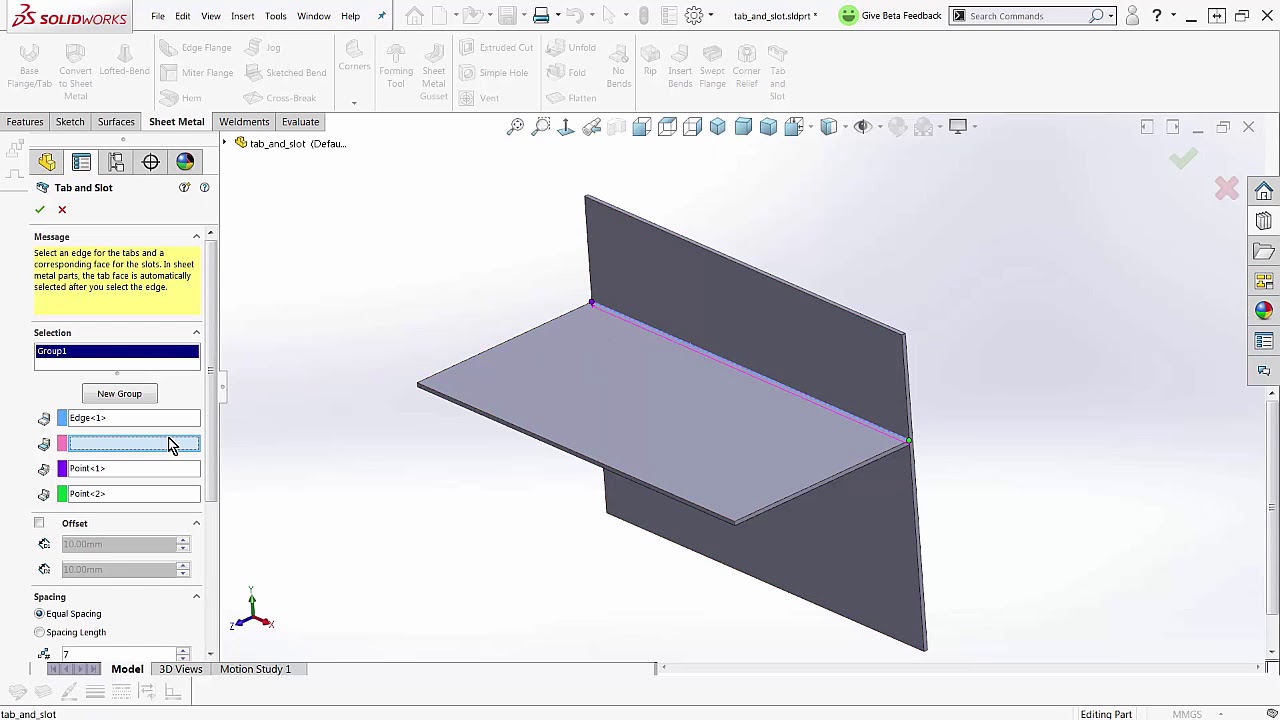

Solidworks has a specific sheet metal features that allow the creation of sheet metal quickly. Otherwise all formats from all standards are listed. Follow simple steps to learn. Today i am going to share some useful tips and trick when creating sheet metal in solidworks.

What i got from that is that i need to take a few days with a lot of sheet metal parts to get the tables as accurate as possible foe sw to give accurate blank sizes for the laser. However in some circumstances when the design requires certain types of geometry you can use non sheet metal feature tools then insert bends or convert the part to sheet metal. This is quick simple tutorial for solidworks beginners starting working with sheet metal. Select a standard sheet size or click browse and locate a custom sheet format file.

Dxf ready for metal fabricator shop. 1 solidworks tutorial for be. To estimate sheet metal part costs with the sheet size option. You might also like.

Select only show standard formats to display sheet formats for the current drafting standard only. Provide feedback on this topic. Stock type from template. In a sheet metal part click costing tools toolbar or tools solidworks applications costing.

True that the tables never over bend the material and part sizes are what i need. Specify a width and height. In the costing task pane under blank size select sheet size.