Solidworks Sheet Metal Internal Flange

1 solidworks tutorial for beginners.

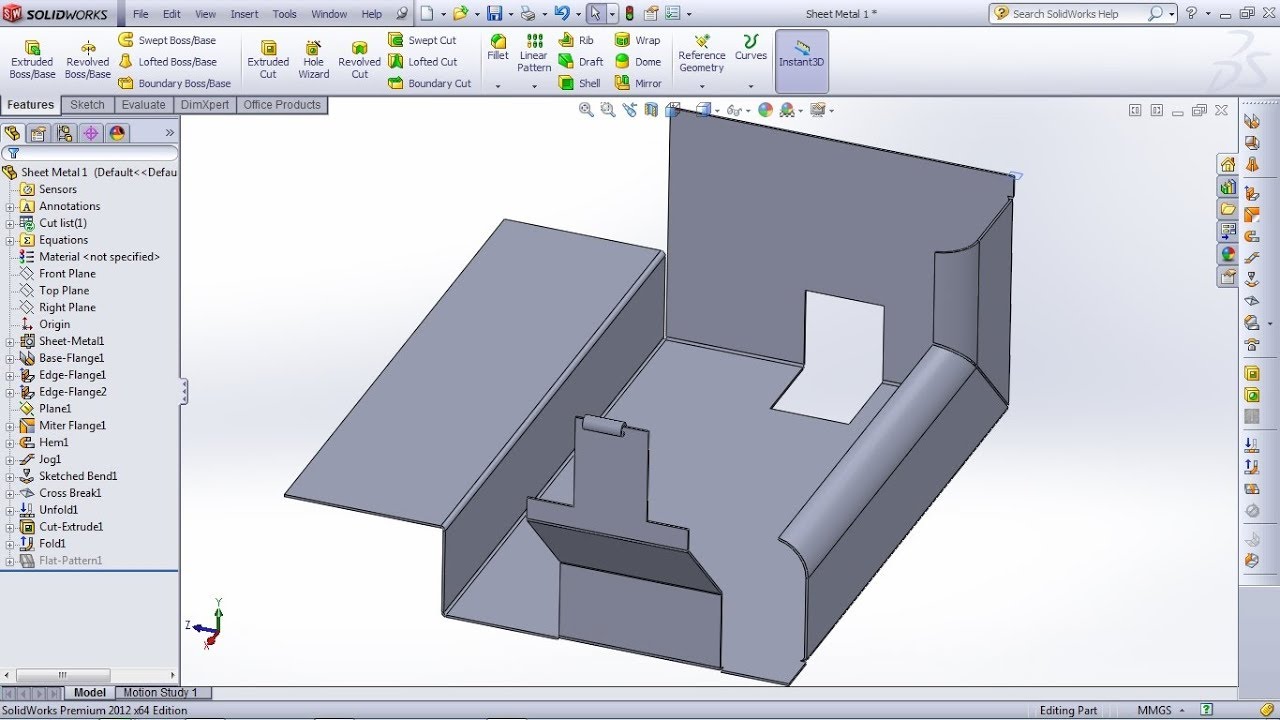

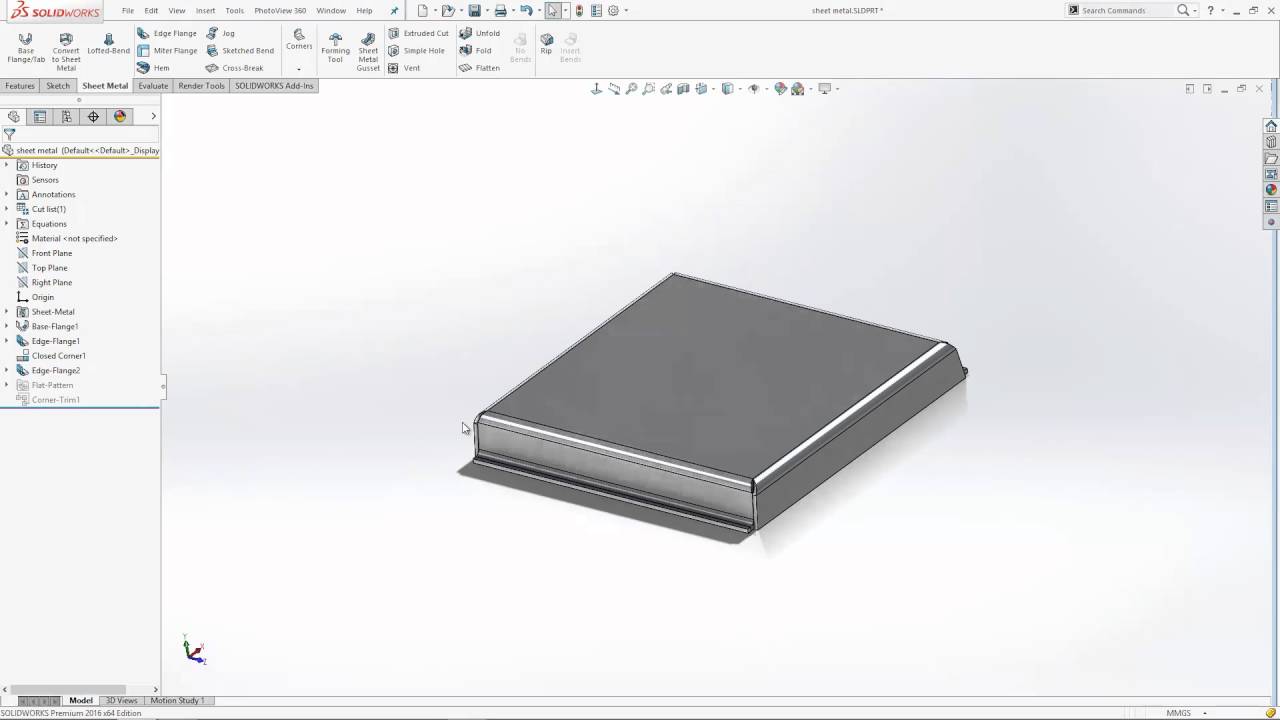

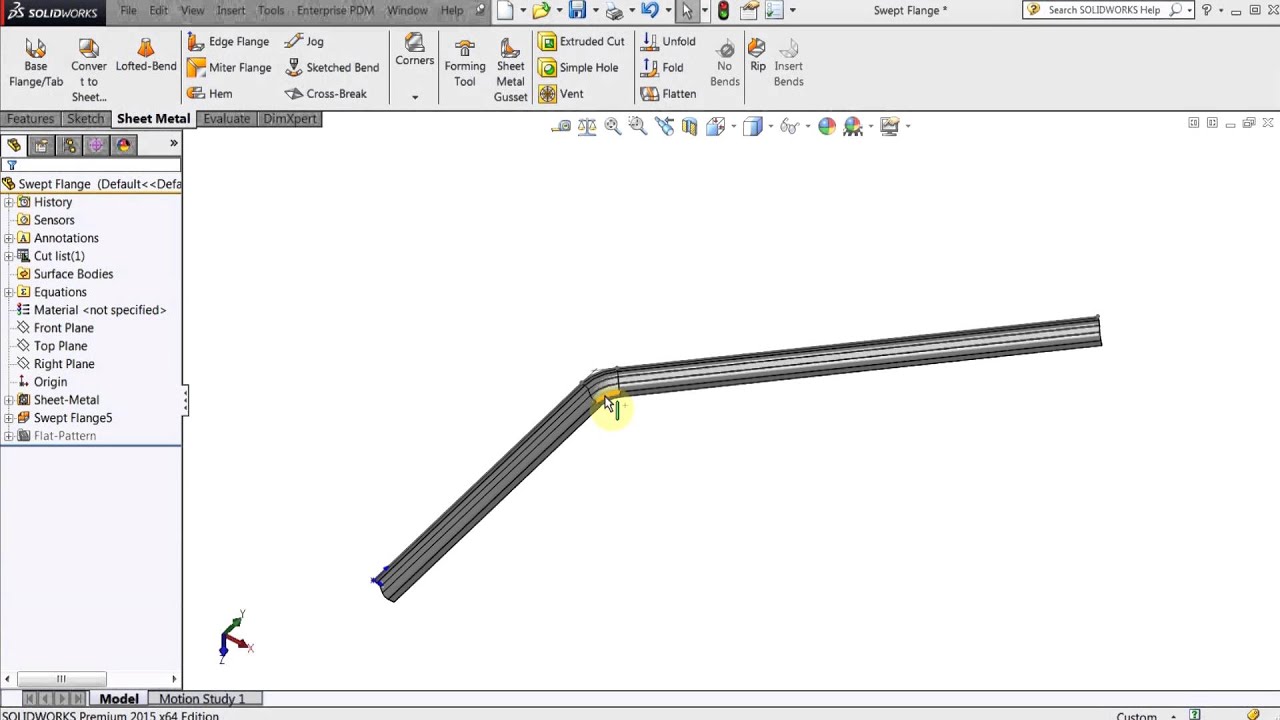

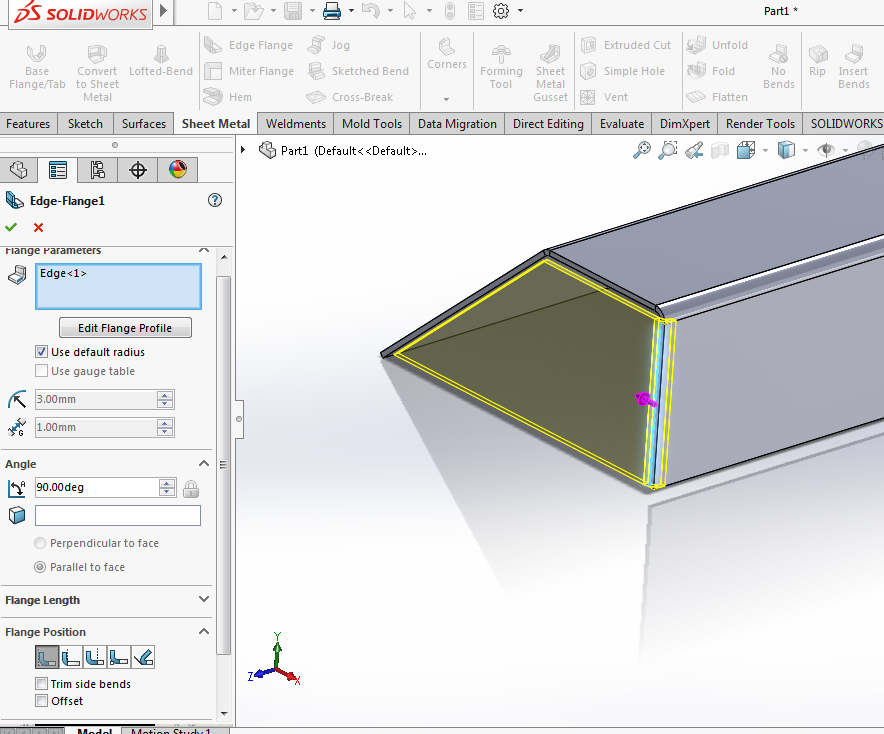

Solidworks sheet metal internal flange. This example shows how to insert a sheet metal edge flange. Unfolded sheet metal before correction. 2019 solidworks help swept flanges for conical and cylindrical bodies i think the flattened sheet should look like the following sketch as the radius and arc length of the upper and lower side of the cylinder should be the same. You might also like.

To report problems encountered with the web help interface and search. There are specific sheet metal features you can use to create sheet metal bodies quickly. But a subsequent reply may correct me on this. There are many other tools that can be used with this software.

This video show how to use solidworks to add mitered edge flanges to an internal corner of a sheet metal part that will unfold correctly. English only 2020 sp04 to disable web help from within solidworks and use local help instead click help use solidworks web help. Create another edge flange on an edge. We will add a 90 degree x 2 50 inch flange create the settings so after the flange is complete the total measurement of the flange will be 2 50 inches and the original length of 6 00 inches will increase by the sheet metal thickness.

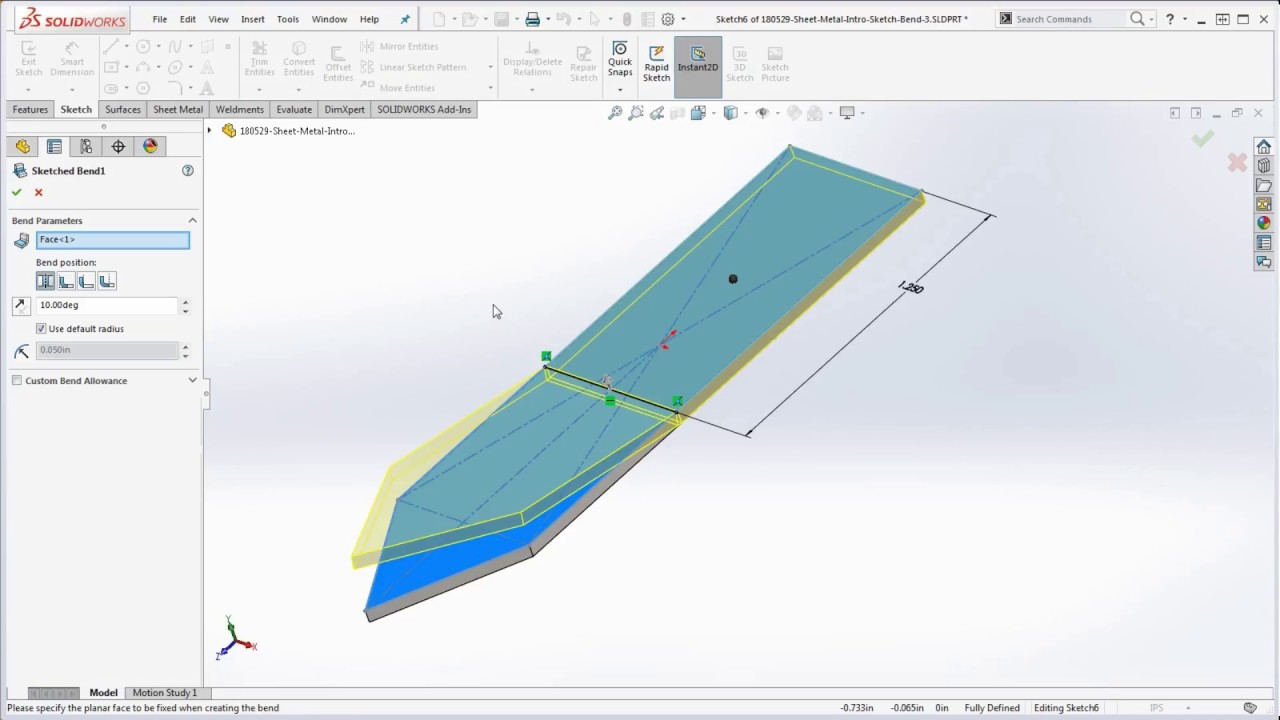

So how to flatten a sweep flange properly. Is it because it includes the deformation of the metal. I believe each flange operation controls all of its bends whether it s one or more. Flange to one of the sides of the base part.

A sheet metal part is open and the edge for. So i think you will have to create a flange operation for each bend that requires a different radius. Thickness is linked to the thickness of the sheet metal part. Folded sheet metal with bottom added after correction.

Miter flange lofted bend corner controls sheet metal gusset and rip are all very common tools that can make life easier for the designer. We will learn sheet metal basic features like base flange edge flange corner relief and extruded cut in solidworks sheet metal. Sketch line of the profile must lie on the selected edge. Focus is on removin.

The completion of the certified solidworks professional advanced sheet metal cswpa sm exam shows that you have successfully demonstrated your ability to use solidworks sheet metal tools.