Solidworks Strain Relief Sheet Metal

If i have a 30mm gap and i want a flange tab with a relief of 1mm my flange should be 28mm leaving 1mm each side of the flange.

Solidworks strain relief sheet metal. A bent sheet metal part is created whose dimensions in the flattened state reflect the specified bend allowance and radius values. In the corner relief propertymanager under scope select the sheet metal body to which to apply the corner relief. Welcome to solidworks simulation help. The distance d is determined by the following equation.

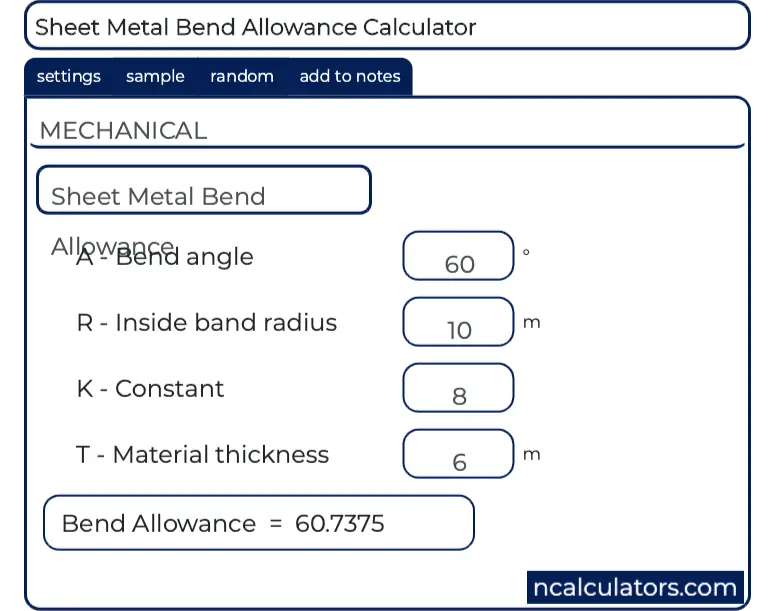

The options and values you specify for bend radius bend allowance and auto relief are shown as the default settings for the next new sheet metal part that you create. You can add a corner relief to a single sheet metal body. K factor most of these factors vary from shop to shop and equipment to equipment so normally each shop sets up their own sheet metal calculations. Lists corners to which you can apply corner relief.

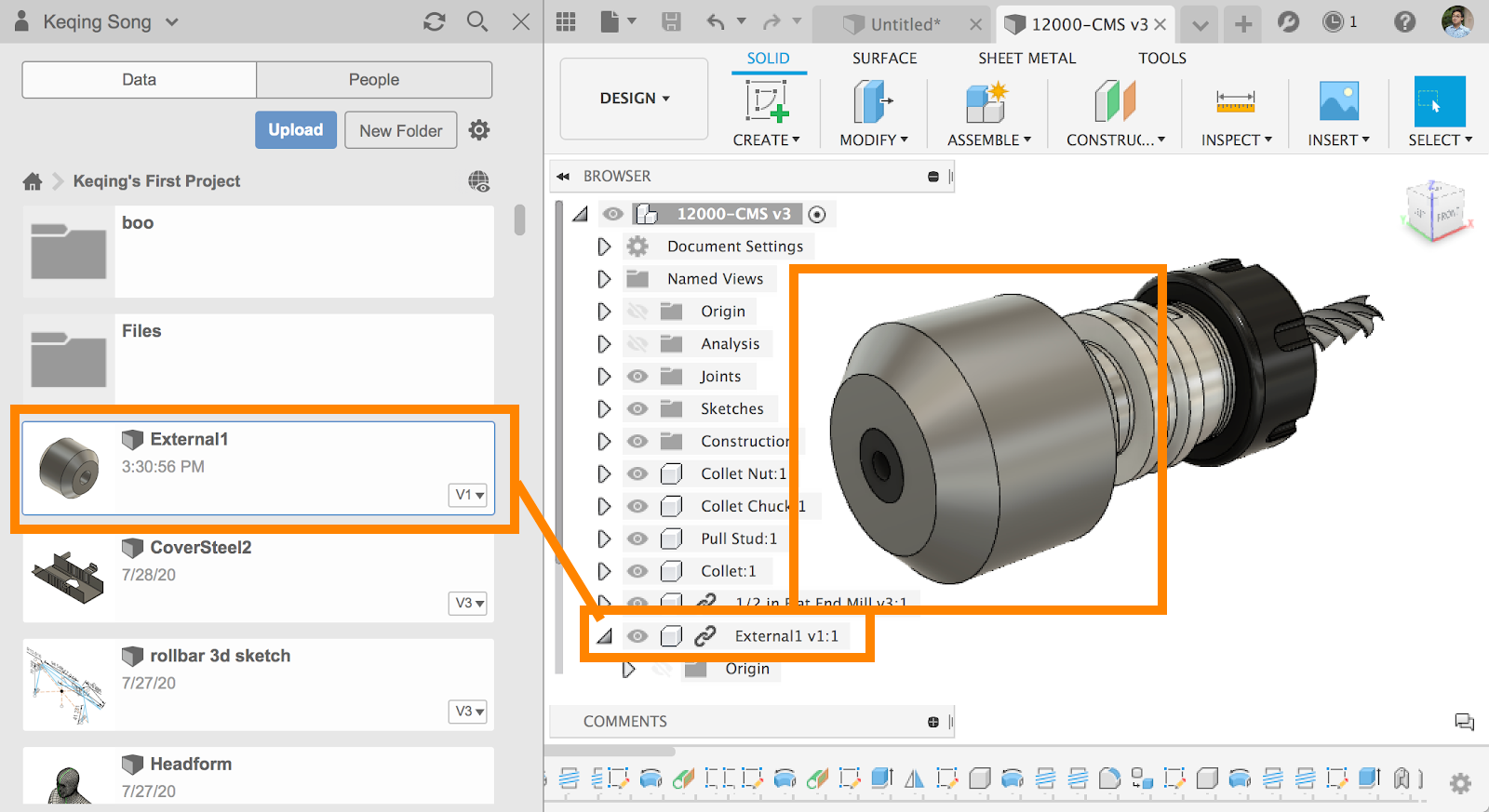

Click corner relief sheet metal toolbar or insert sheet metal corner relief. Select keep body if you want to keep the solid body to use in another convert to sheet metal feature. The relief gap should be across the full length of the flange. Set the sheet thickness and default bend radius.

The distance d represents the width of the rectangular or obround relief cut and the depth by which the side of the rectangular or obround relief cut extends past the bend region. Sheet metal functionality within solidworks provides designers with powerful tools to create accurate formable models of their designs. You can add a corner relief to a single sheet metal body. Lets you select the sheet metal body to which the corner relief is applied.

When you select a corner it is highlighted in the graphics area. Solidworks welcomes your feedback concerning the presentation accuracy and thoroughness of the documentation. Accessing and using help. When cleared the body is consumed by the convert to sheet metal feature.

Click corner relief sheet metal toolbar or insert sheet metal corner relief. However a common point of confusion when using sheet metal functions is the difference between the auto relief and corner treatment tools. In real life manufacturing you cannot cut anything without losing some material. In the corner relief propertymanager under corner type select a two or three bend corner.

Solidworks 2019 sp05 to disable web help from within solidworks and use local help instead click help use solidworks web help. Strain is a dimensionless quantity. Select a face as the fixed face for the sheet metal part. Under corners click collect all corners to list all corners in the sheet metal body.

Under scope select the sheet metal body to which to apply the corner relief. D relief ratio part thickness the bend region is represented by the dark gray area of the diagram. Solidworks keeps the bend thickness consistant with the sheet metal gage. Under corners click collect all corners to list all corners in the sheet metal body.