Springback In Bending Of Sheet Metals And Plates

After a bending operation residual stresses will cause the sheet metal to spring back slightly.

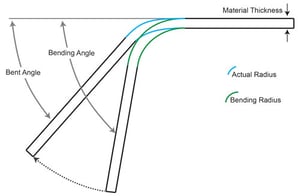

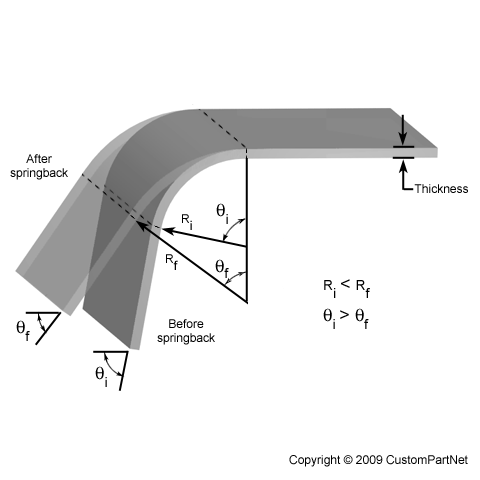

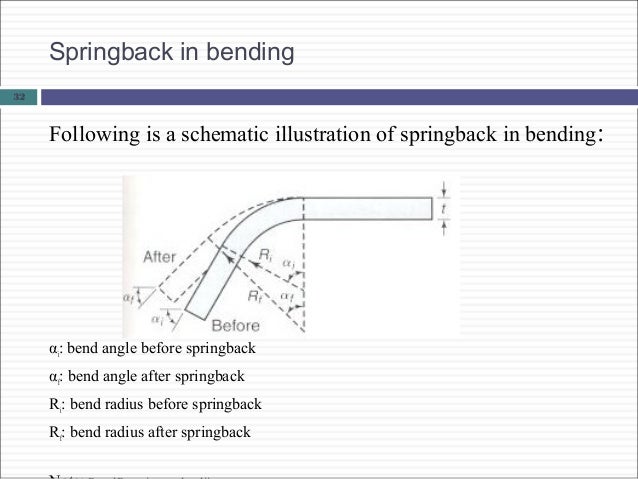

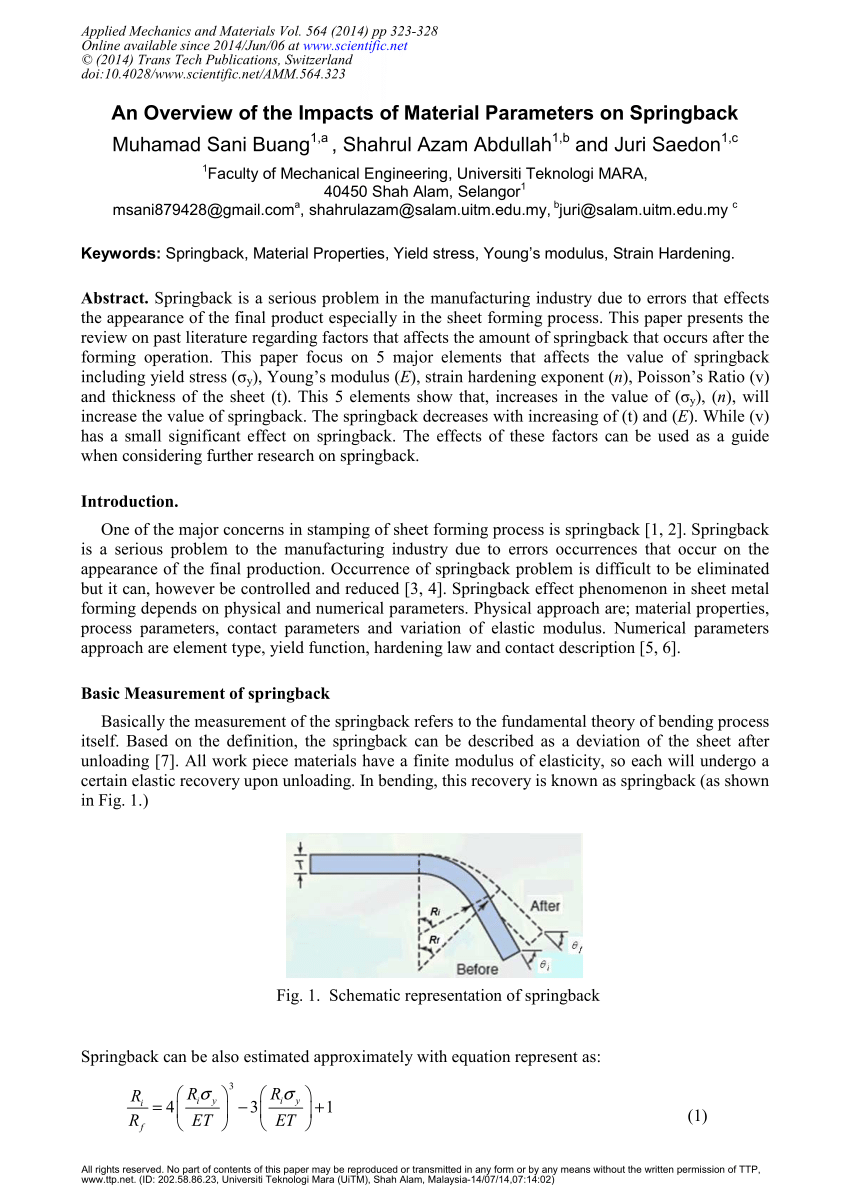

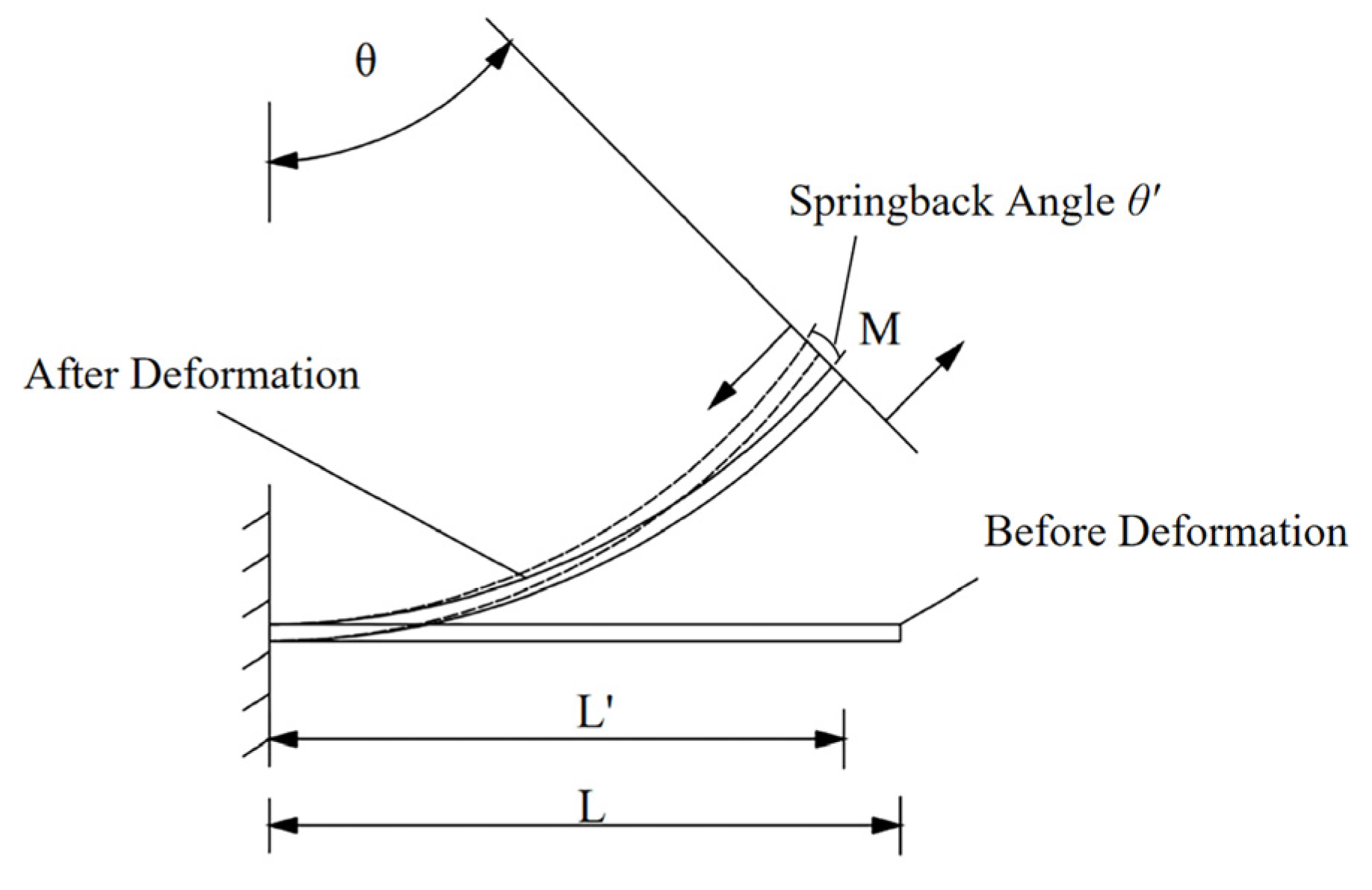

Springback in bending of sheet metals and plates. It can be can be understood by looking at a material s stress stain curve discussed in the module on tensile testing which characterizes the behavior of metal under applied force. While sheet metal gauges run from 0 005 to 0 249 inch thick aluminum and steel plate thicknesses start at 0 250 in. The springback can be reduced by the way that the deformation of plate exceeds the theoretical deformation degree. A depiction of springback in a simple bend can be seen in figure 1.

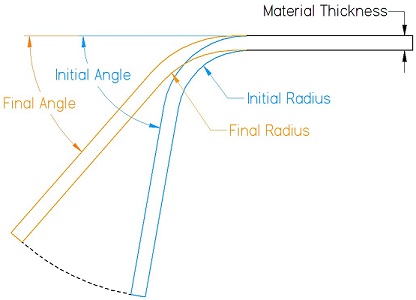

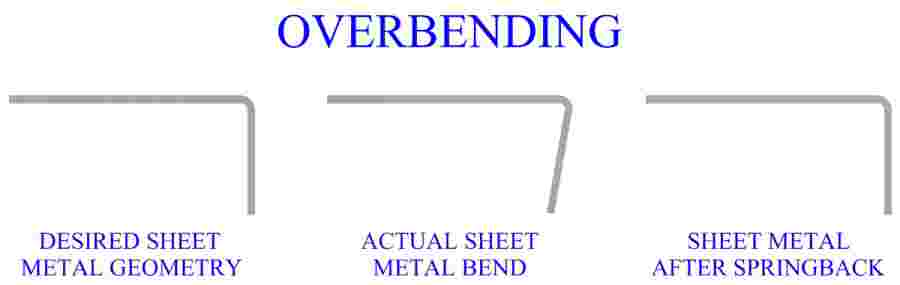

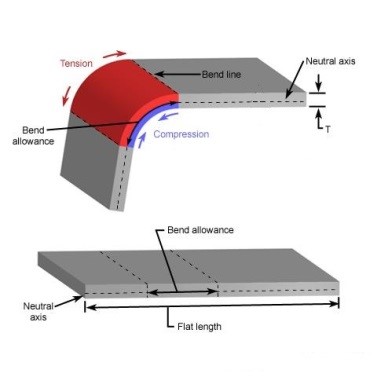

This distortion is termed springback. In bending production the deformation angle and radius of sheet metal will be increased due to elastic recovery. Due to this elastic recovery it is necessary to over bend the sheet a precise amount to acheive the desired bend radius and bend angle. Bending is one of the most common sheet metal fabrication operations.

The formation of sheet metal requires elastic plastic bending and stretching of the metal which contributes to springback. The force must exceed the material s yield strength to achieve a plastic deformation. Sheet metal bending bending of sheet metal is a common and vital process in manufacturing industry. Sheet metal bending is the plastic deformation of the work over an axis creating a change in the part s geometry.

2 the stainless steel sheet has a strong rebound tendency compared with carbon steel when bending. The curved line in the air forming zone shows how springback changes at different bend angles. This springback and inside radius calculator estimates the amount of angular change and the relaxing of bend radius that occurs when metal is bent and released from pressure when the proportional limits of a specific material are reached or exceeded the material remains bent figure one. Figure 3 coining bottom bending and air forming affect stressstrain properties differently.

In bottoming and coining bending methods that usually produce 90 degree bend angles the line curves to the right of the vertical axis showing how the metal springs forward to conform to the die angle. Likewise plate steel varies in strengths from mild varieties to some very high strength materials such as hardox. Springback is inherent in sheet metal forming. Also known as press braking flanging die bending folding and edging this method is used to deform a material to an angular shape.

Springback is known as the reaction when this metal is bent and causes complications when forming the metal into objects such as seams. This is done through the application of force on a workpiece. Bending is one of the most frequent actions done to metal in press brake operation. When it comes to very thick or high tensile strength material.