Stamped Sheet Metal Design Parameters

The sheet features a union jack style perforated design.

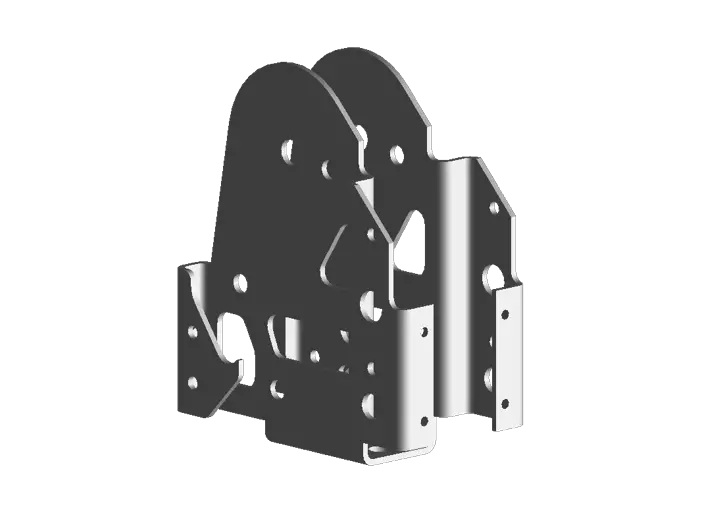

Stamped sheet metal design parameters. A robust review process will outline any application specific expectations or requirements to determine the best material and metal stamping process for the job. This is because of its efficiency in bulk forming operations. Mill aluminum union jack style perforated sheet metal offers a decorative way to complete your hvac door window hobby and cabinet projects. At normal temperature a metal or non metal sheet is pressed on a stamping press machine by a stamping die to cause separation or plastic deformation thereby obtaining parts having a certain shape size and performance.

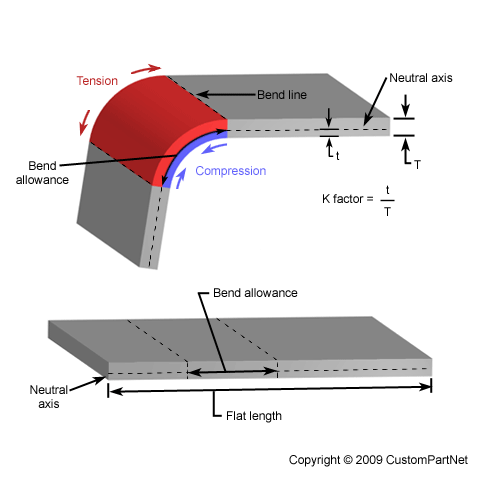

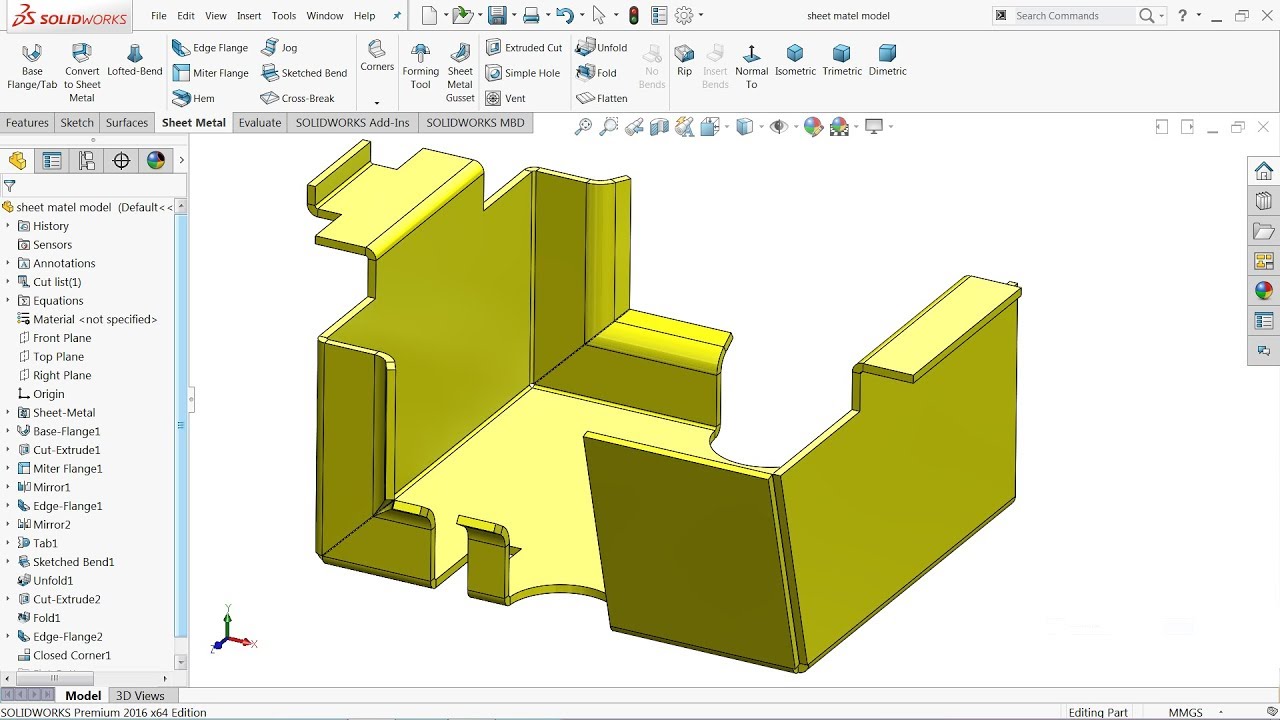

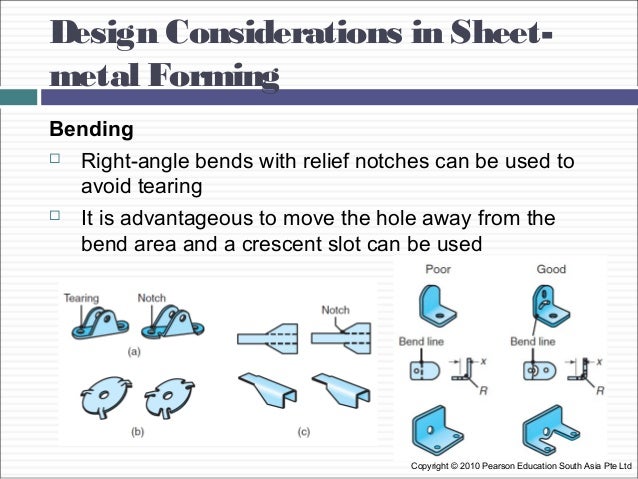

The definition of stamping. Design for manufacturability dfm. Typical sheet metal thicknesses used in stamping are 0 001 in. Basic knowledge of metal stamping process.

Hole standard whenever a hole is created a design table will associate its radius with a standard name. X 36 the md building products 36 in. It is easy to work with and very attractive in the home. Sheet metal stamping is widely implemented in automobile industries to convert sheet metal into exterior and interior parts such as auto body panels and also a variety of appliance parts with prescribed sizes and shapes.

Specially designed sheet metal stamping dies are made and used for increased production efficiency. 1 1 metal stamping process characteristics and applications. Selected bending tool parameters. Here is an example for the use of a stamp standard file.

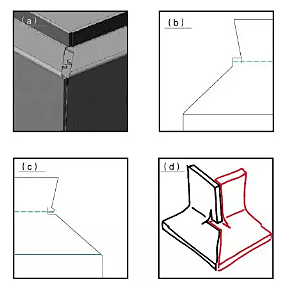

Masood in reference module in materials science and materials engineering 2016. Main sheet metal parameters design table. The metal stamping team should review the manufacturer s print submission to estimate quality tooling engineering and production parameters. It is always better to specify hole diameters that are greater than the sheet s thickness t.

The md building products 36 in. Pieces of flat sheet metal typically referred to as blanks is fed into a sheet metal stamping press that uses a tool and die surface to form the metal into a new shape. In the design of sheet metal structure the rigidity of sheet metal structural parts is often not met. For example a flip hole tapping of a m4 with a 1 5 mm sheet bent the d value should be greater than.

Although most stamping operations use sheet steel special dies can cut and form steel bars up to 3 in. Main sheet metal parameters design table.