Standard Punch Sizes Sheet Metal

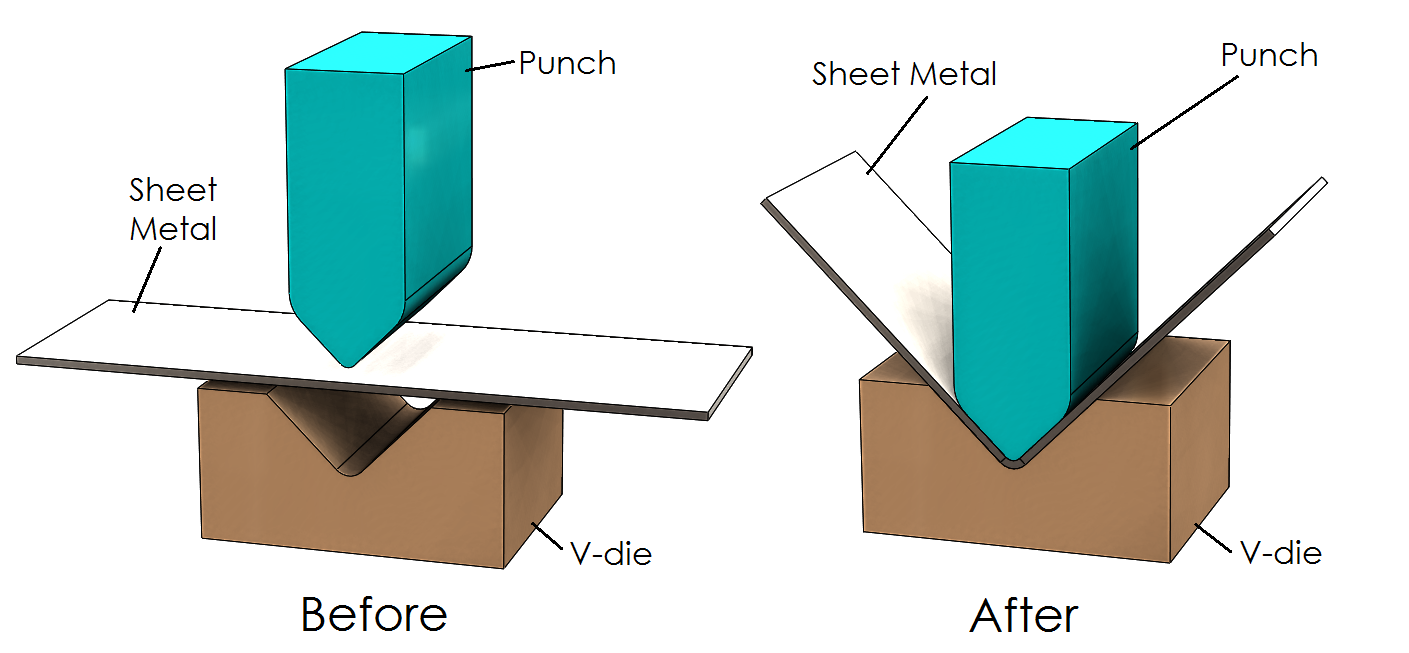

Sheet metal is one of the fundamental forms used in metalworking and it can be cut and bent into a variety of shapes countless everyday objects are fabricated from sheet metal.

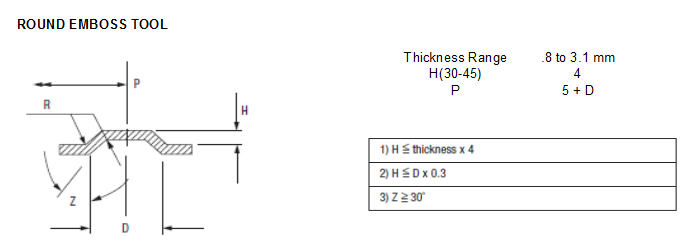

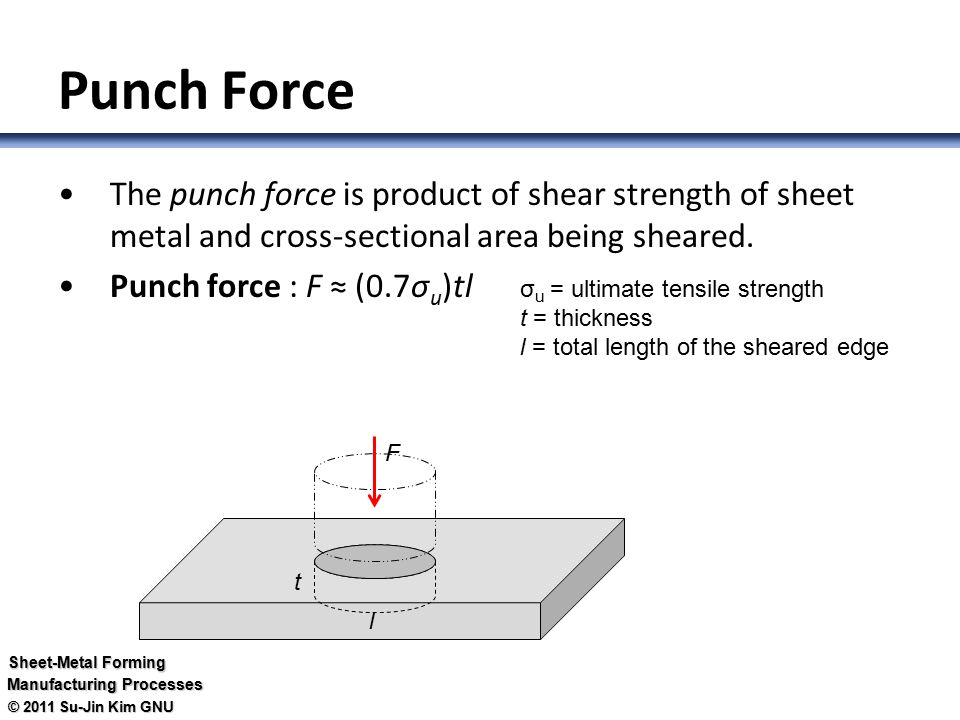

Standard punch sizes sheet metal. Create a raised edge in sheet metal that locks into the rolled edge of another piece. Thicknesses can vary significantly. Many other shapes can be created by using two or more cnc tools together such as key hole slots rectangular cut. The thickness of sheet metal starts from 0 5 mm and goes up to 6 mm.

Sheet metal hole flaring dies. Extremely thin sheets are considered foil or leaf and pieces thicker than 6 mm 0 25 in are considered. Sheet metal is the next in line. The point automatically centers once the punch has fit the hole size.

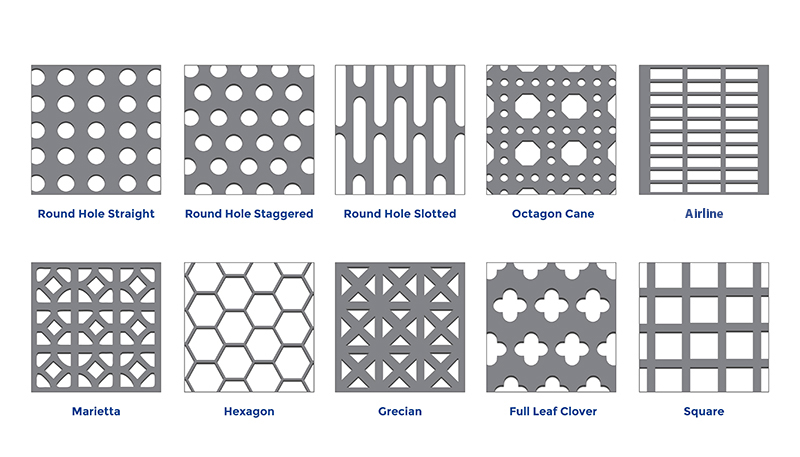

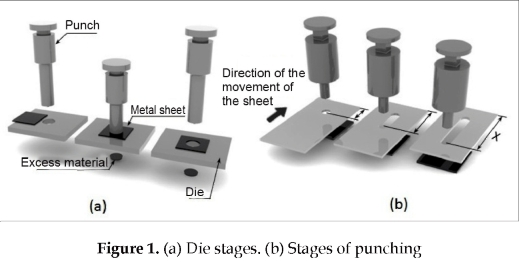

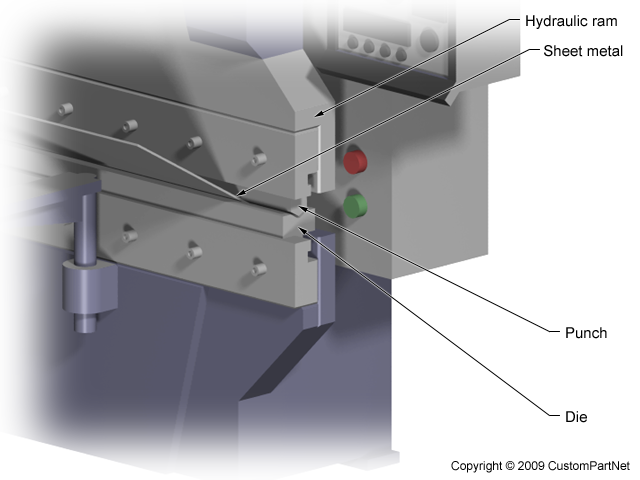

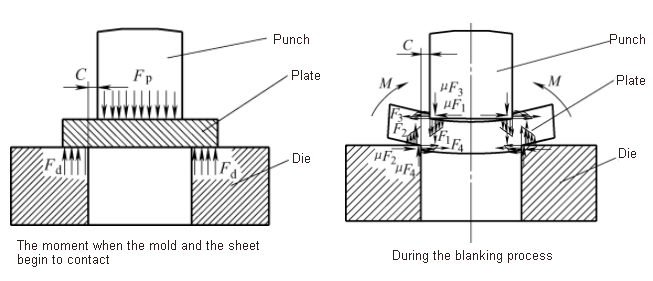

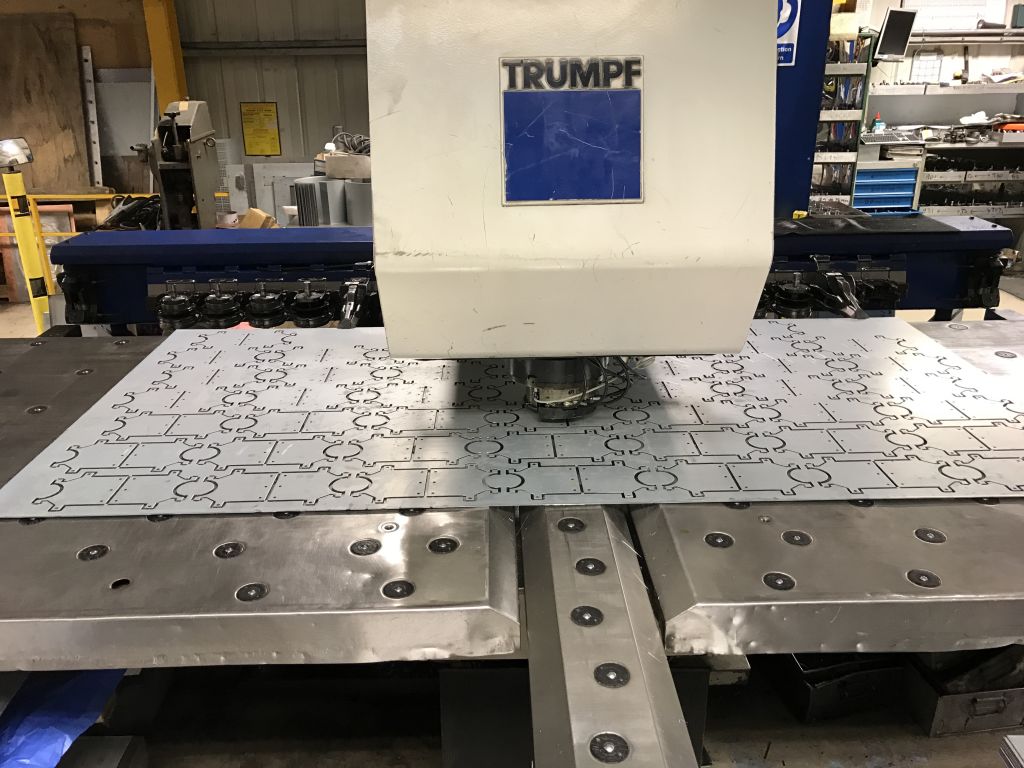

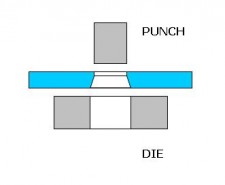

Please use the standard cnc punch tooling shapes below as links to the most common tooling tables. A locking clamp eliminates the need to thread the punch onto the stud making setup and disassembly quicker than with standard punches. While once sheet metal punching was done manually today the technique of metal punching uses automatic machines with numerical control. Stock sizes of oblong round and square ironworker punches and dies american punch company manufactures the most trusted punches and dies used in the steel fabrication industry.

Create flares around already cut holes in sheet metal up to 3 16 thick to make the edges. We normally recommend the following clearance hole sizes for common size american bolts 5 16 for a 1 4 inch screw 3 8 for a 5 16 screw and 7 16 for 3 8 bolts and 9 16 for 1 2 bolts 11 16 for 5 8 bolts 13 16 for 3 4 bolts 1 1 16 for 1 bolts. Sheet metal is metal formed by an industrial process into thin flat pieces. At a relatively cheap price it makes a great fit for most engineering purposes.

The die size options are a guide to the material thicknesses that we can punch with each set of tooling. They come with punches and dies in varying sizes. That is why we see it everywhere around us. Anything above that is a metal plate.

The thin sheet metal is easy to form while still providing great strength. Sheet metal hole flaring dies. 0 2mm die clearance can be used from 0 4mm 2 0mm and sometimes above depending on material specification. Less clearance may be needed for very thin sheet metal.

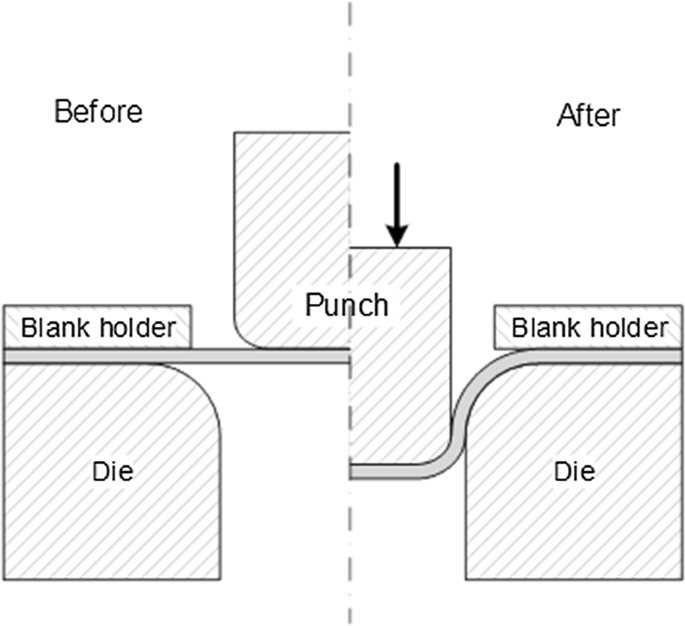

Our durable punch die sets provide the repeatability and dependability your operation demands. Compact portable lever operated hole punches. The automatic punching machines use punches and matrices of standard or special shapes based on the final design that you want to achieve. The tables detail all the cnc punch hole sizes that you can define within your sheet metal fabrications without any tooling costs.

These punches are half the size of standard portable lever operated punches.