Steps Polishing Edge Acrylic Sheet

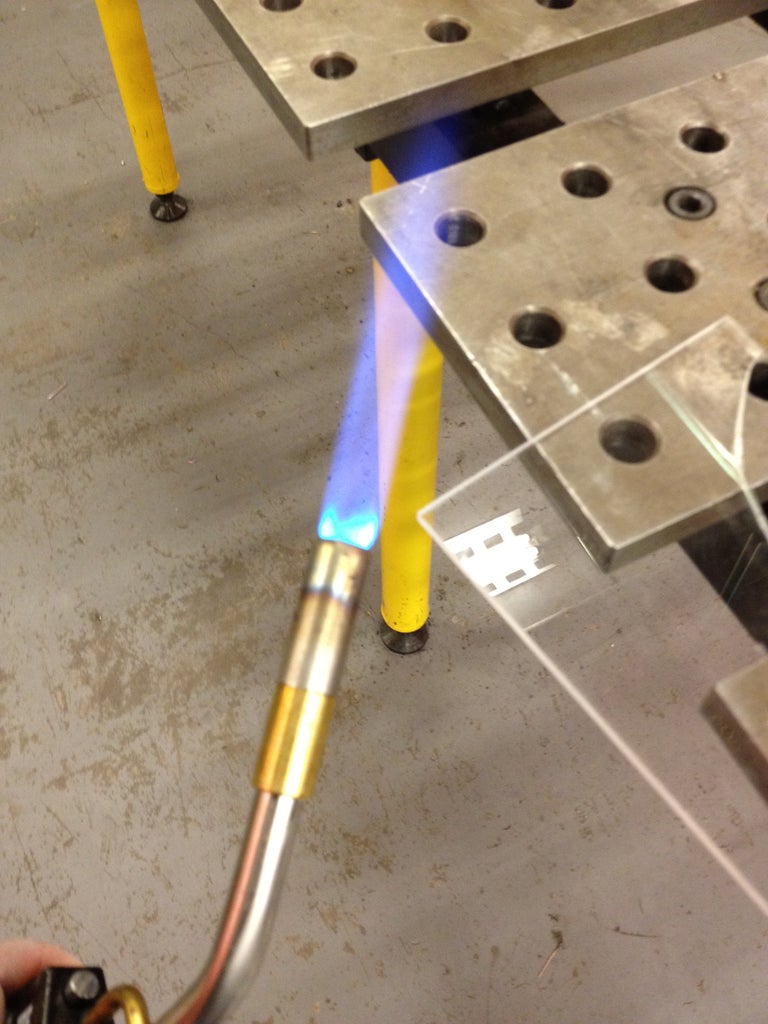

The sudden heating of the sheet when flame polishing induces a high degree of stress into it.

Steps polishing edge acrylic sheet. 2 once a piece of acrylic has been cleaned its brilliance can really shine through with engraving while cleaning acrylic can bring out the its. Buffing is done after the polishing process has been completed giving the edges an even higher quality polished finish. You must use propane torch. The best method is to use a polishing bit to finish the job at the router.

Now use 1000 grit. Check for slipping. You can use a torch to polish the edge and make it shine. Butane does not burn at the right temperature.

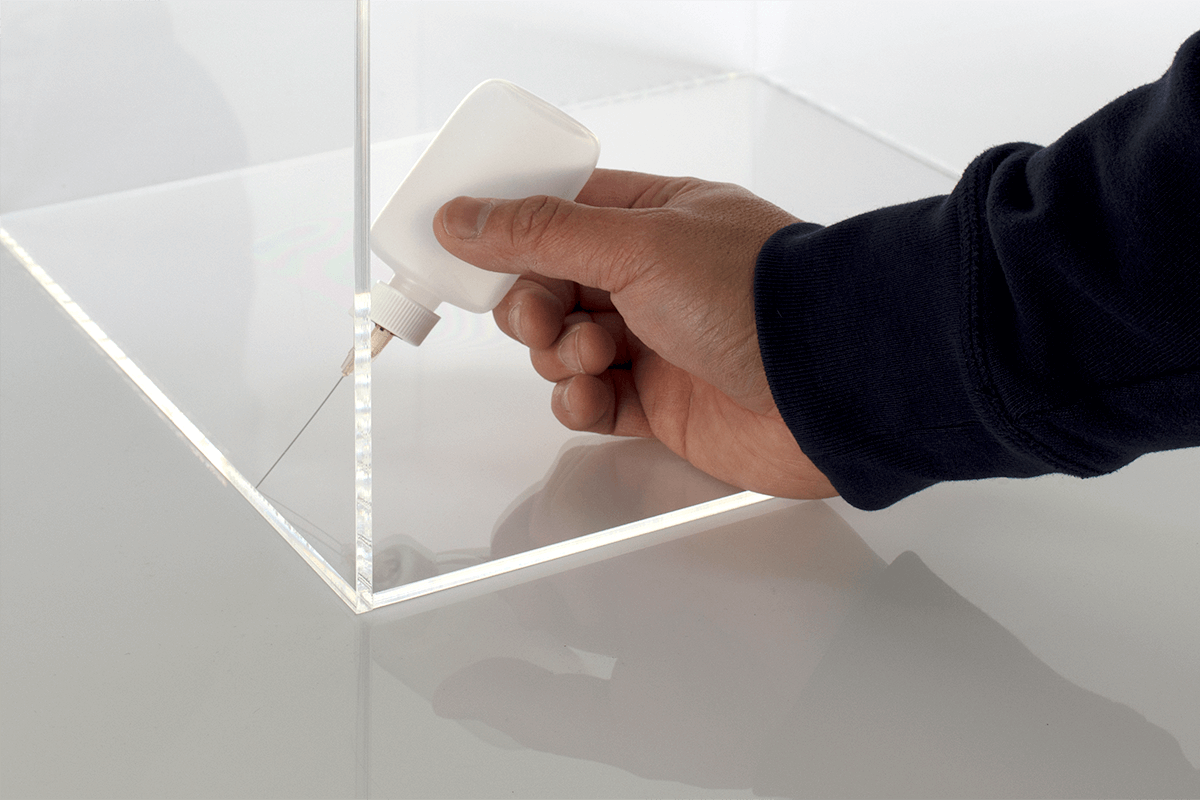

But before we get to that we should point out now that once the edge of an acrylic sheet has been polished it cannot be glued. For the best aesthetic result you can polish the edge until the edge is crystal clear polishing pastes such as zvizzer heavy cut and fine cut polishing agent that have been specially developed for acrylic are available for this task. This step is optional. Apply the paste on the edge and gently work over the edge with the buffing pad.

Simply pass propane flame torch over edge in a slow and steady pace. To polish acrylic sheet edge. You will also need a polishing disc and a drilling machine. Polishing acrylic edges is not difficult but as stated above the process can be time consuming and if you use the wrong tools you can severely damage the material.

Place the polishing felt on the sander and apply the polishing give the edge of the acrylic glass a finished polish. The polishing tool path needs. Its not hard to do but requires access to some fairly special tools ideally an ox. After you ve sanded the edge and removed all plastic from the glass you can use a torch to polish the edge and make it shine.

If the first pass does not produce a completely polished edge allow the piece to cool and then try a second pass. Make sure to re spray the acrylic as you switch sandpapers. Diamond polishing goes together with a buffing process. Practice will help you to estimate the speed and distance.

Please note that if you choose to polish your acrylic sheet this is our standard polishing method. Hold the torch at the angle shown and draw the flame along the edge of the sheet. Wet sanding is what allows you to polish the acrylic and make it look shiny and new. Use lukewarm water and spray evenly making sure to wet every part of the acrylic piece.

You might also enjoy. Because of its thermal stability flame polishing is a bit challenging with this acrylic. As part of a new instructable i realised i would need to use a technique i haven t seen documented here before and that is the flame polishing of thermo plastics. The edge of the acrylic glass is ready for lighting edgelet light panels.