The Impervious Steel Sheet Pile Wall Part 2

The lack of such a methodology can lead to an uneconomic design.

The impervious steel sheet pile wall part 2. The individual vinyl sheet piling pieces are dual interlocking u shaped and 12 304 8mm wide by 8 203 2mm deep and extruded to custom lengths. Of impervious steel sheet pile walls. Grades of sheet piling steel. The impervious steel sheet pile wall.

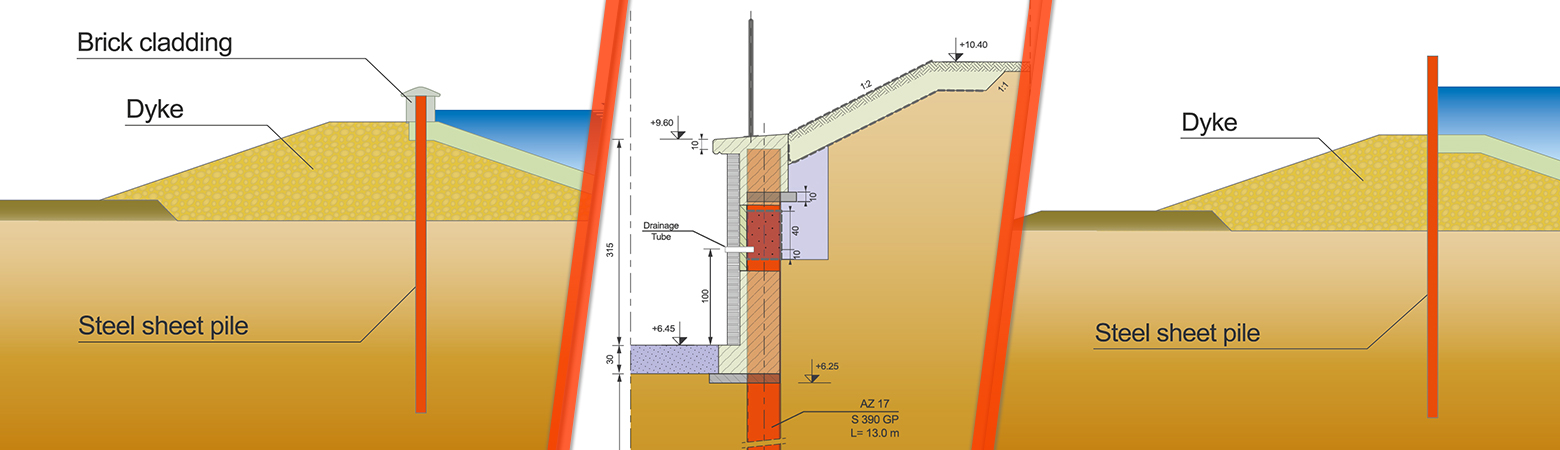

Steel sheet piling is a technology that can be utilized to achieve the objectives of modernization and improvements of dykes and flood walls. V k i 1. Arcelormittal carried out an extensive research project in collaboration with delft geotechnics. Published under licence by iop publishing ltd iop conference series.

Earth and environmental science volume 95 issue 2. Resistance of steel sheet pile ssp walls. The ability of a sheet pile section to perform is dependent upon its geometry and the soils it is driven into. This grade has been satisfactory for most applications in that it provided a relatively high yield point for design and a high ultimate strength for drivability.

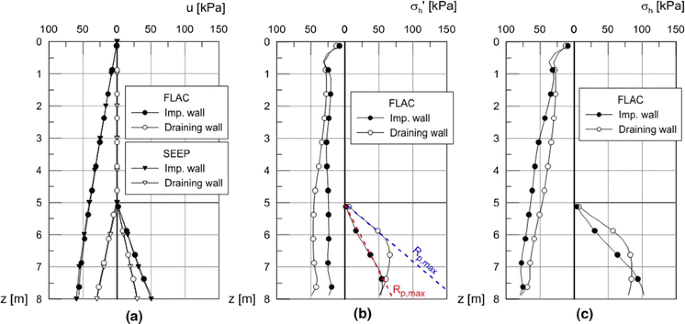

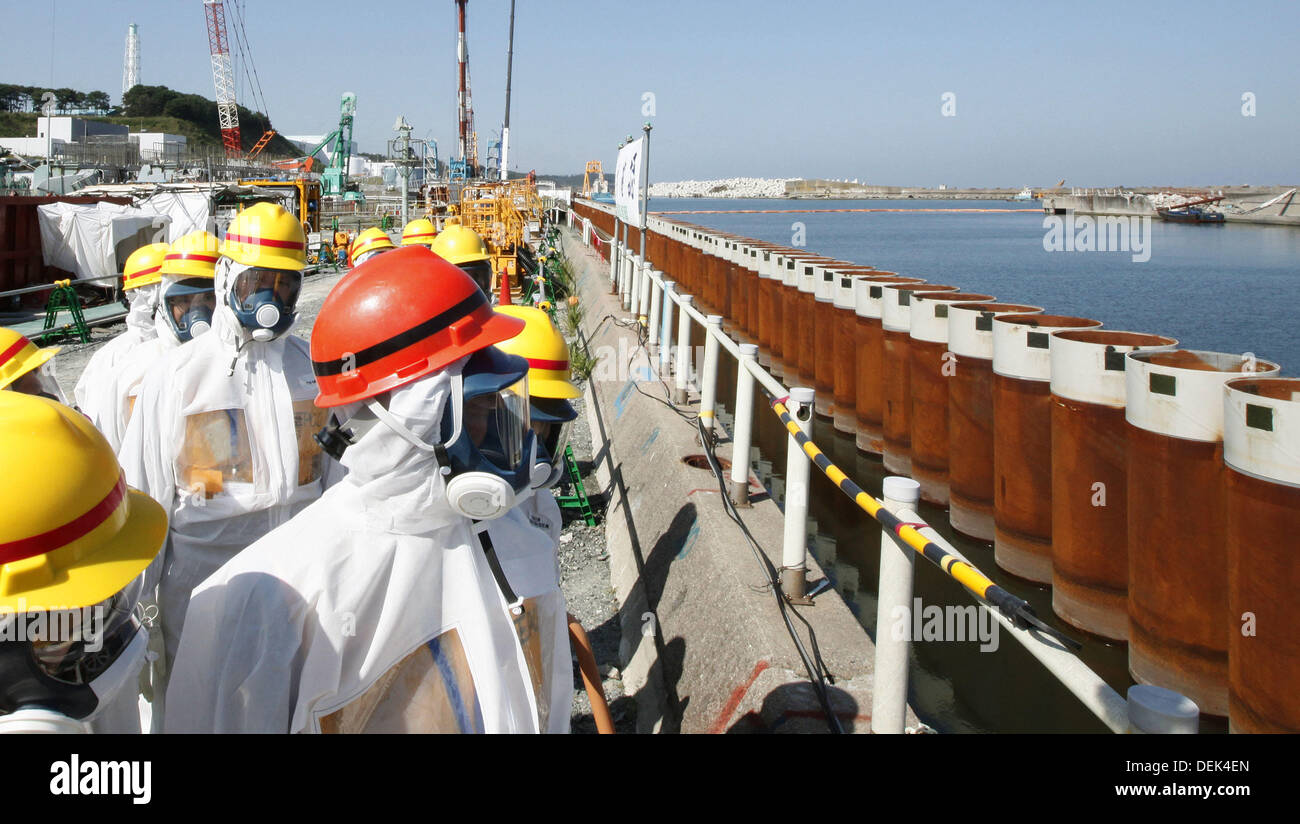

Influence of surrounding soil conditions and joint sealing on seepage resistance of a sheet pile wall three dimensional numerical analyses. Eugeniusz sawicki 1 and marek wyjadlowski 1. This case study focuses on the modernization and reconstruction of the wroclaw floodway system currently the largest european flood protection project under construction and the radunia channel in gdansk. Timber sheet piles have light weight and as such the equipment required for pile driving is also light.

Steel sheet piles steel sheet pile is a rolled steel section consisting of a plate called the web with integral interlocks on each edge. Until the end of the 1980 s no consistent methodology was available for the assessment of the seepage. Steel sheet piles are long structural sections with a vertical interlocking system that create a continuous wall. This is considered to be an important advantage timber piles have over piles of other materials.

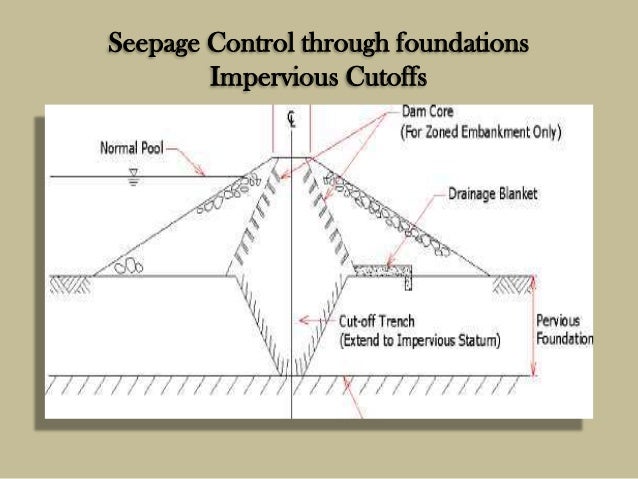

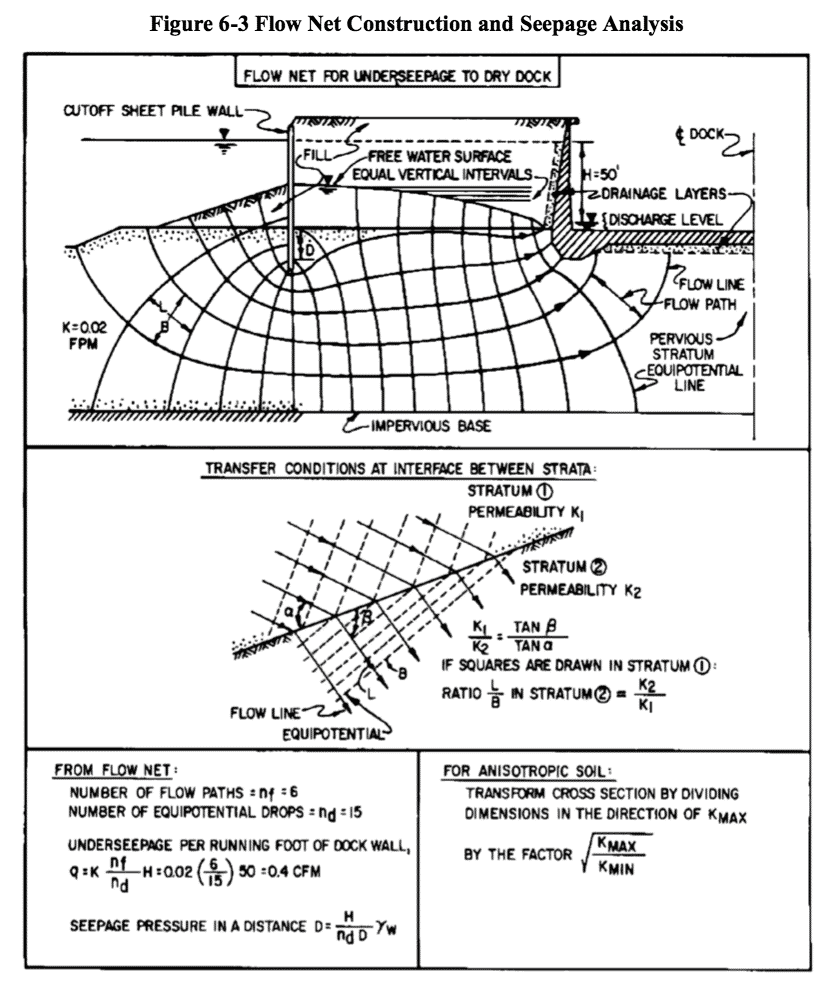

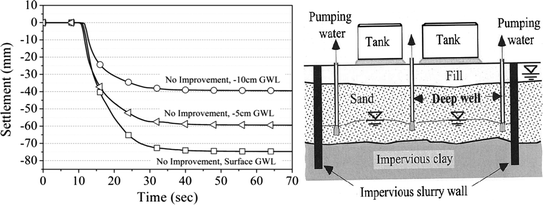

The objective of the project was to determine the rate of seepage through the interlocks of steel sheet piles for various joint filler materials as well as for empty and welded joints. For porous medium like slurry walls the seepage problem can be treated with the aid of darcy s law with a suitably chosen coefficient of permeability k. The latest technology for sea walls is a hybrid system that combines the benefits of a strong steel reinforced concrete wall with the benefits and protection of vinyl sheet piling.

.PNG)