The Sheet Metal Punching Process Explained

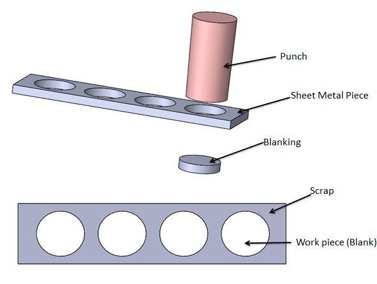

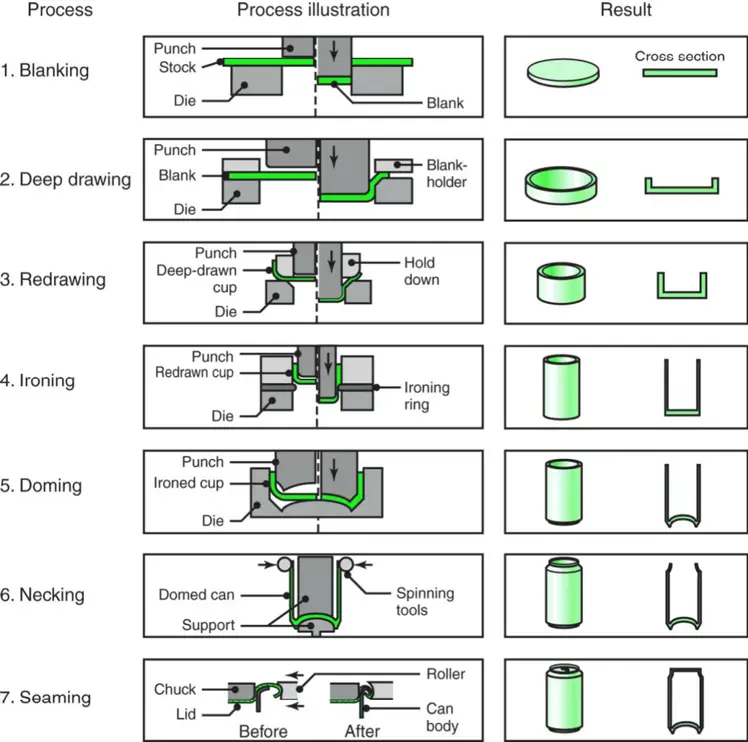

Generally the punching process includes hole punch corner notch hole punch blanking punch convex hull tearing draw hole etc.

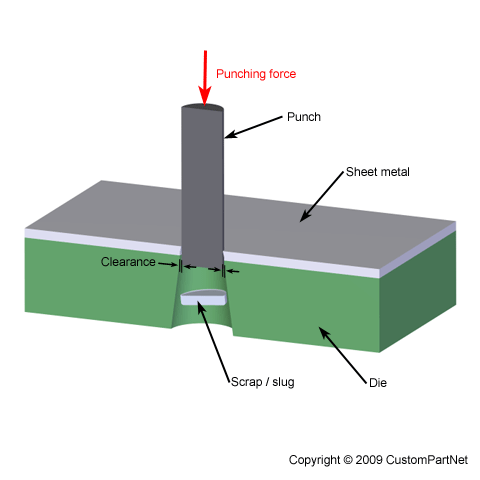

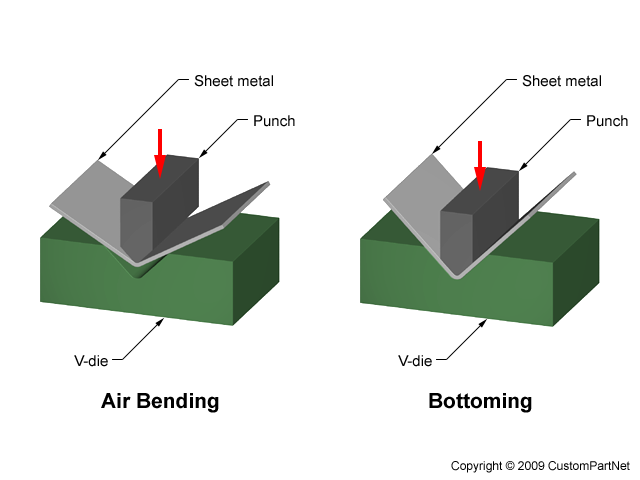

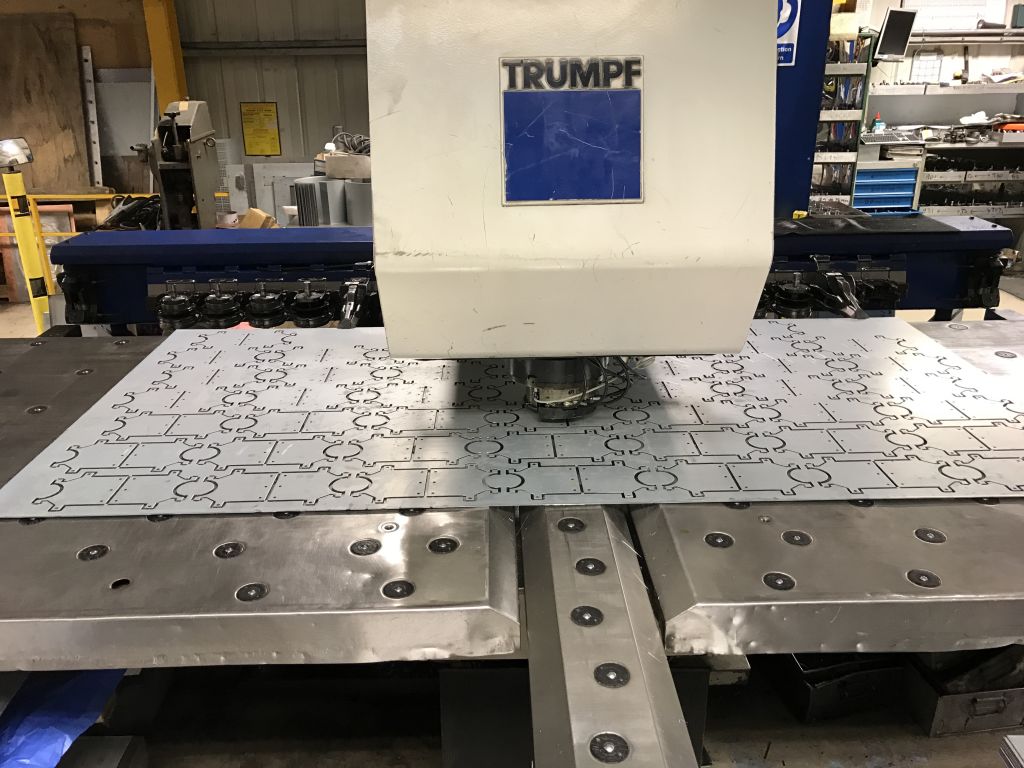

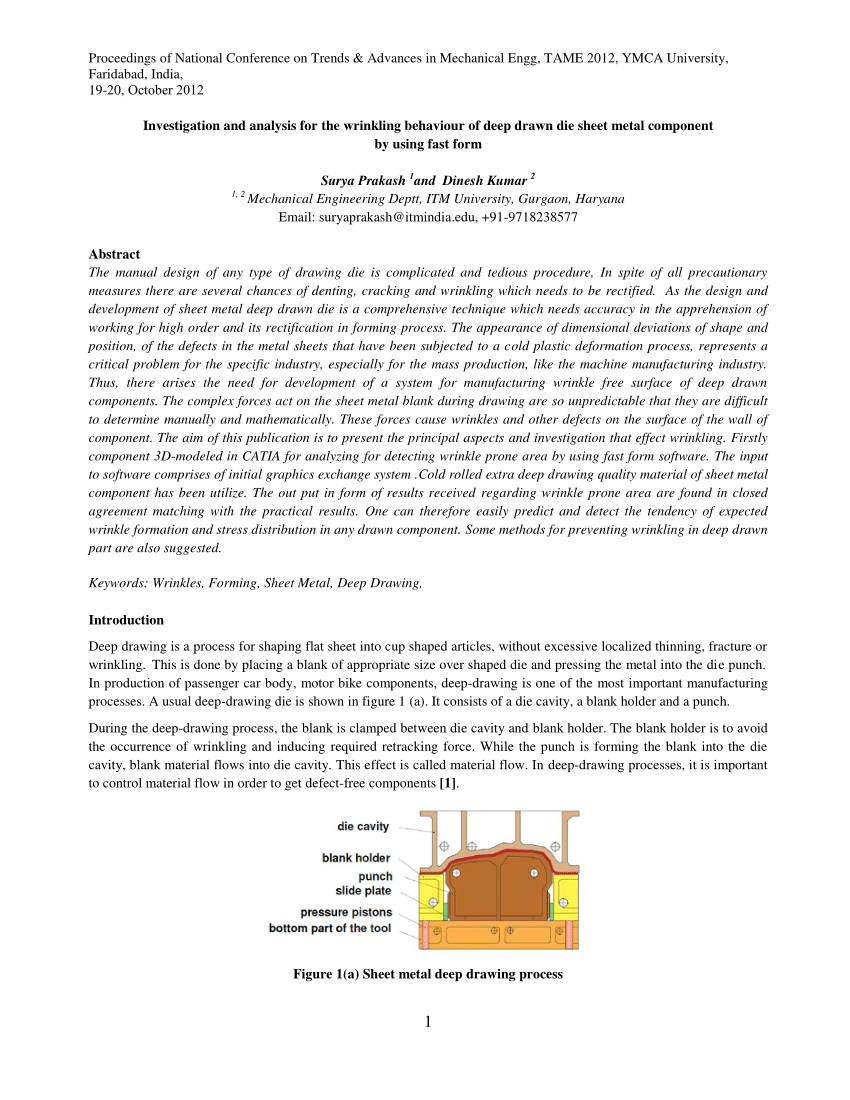

The sheet metal punching process explained. It generally consists of a press frame a bolster plate and a ram. The ability of a cnc punch to achieve this kind of shaping is a large part of the reason why sheet metal punching may be used in place of laser cutting for many custom metal forms. Whereas the punching process aims to punch a hole through sheet metal stamping aims to deform the metal to create specific shapes such as a vent opening or an indent. Punching is a forming process that uses a punch press to force a tool called a punch through the workpiece to create a hole via shearing punching is applicable to a wide variety of materials that come in sheet form including sheet metal paper vulcanized fibre and some forms of plastic sheet.

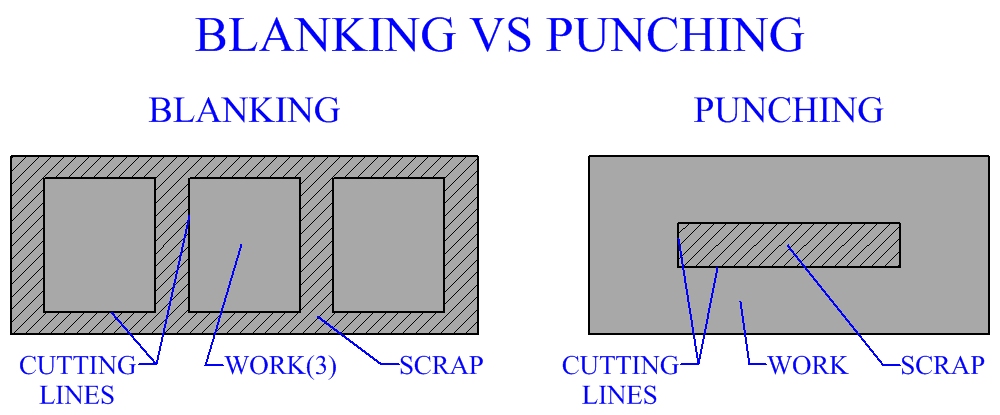

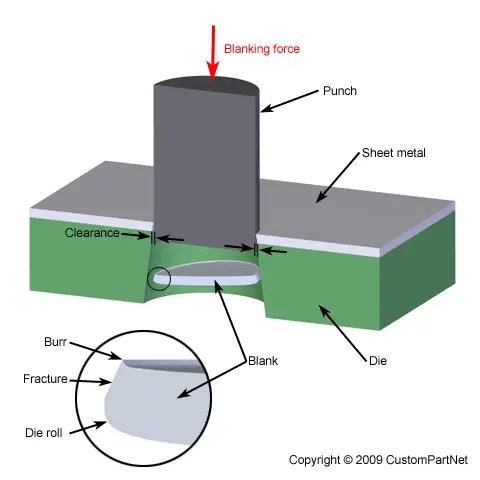

As explained above punching operation removes scrap from the larger piece of sheet metal. It is a metal removal operation. A screw press is also known as a fly press. In other words combination of punching operations modify existing blank sheet using metal removing operations.

No tags for this post. The maximum sheet density is up to 4 mm. This process leaves a hole in the metal workpiece. Its ability to produce economical holes in both strip and sheet metal during medium or high.

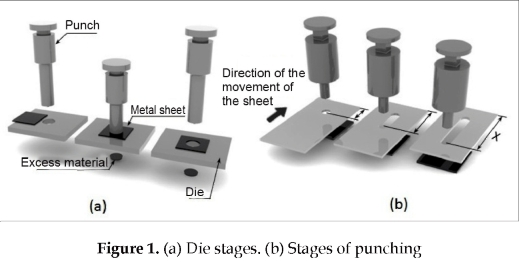

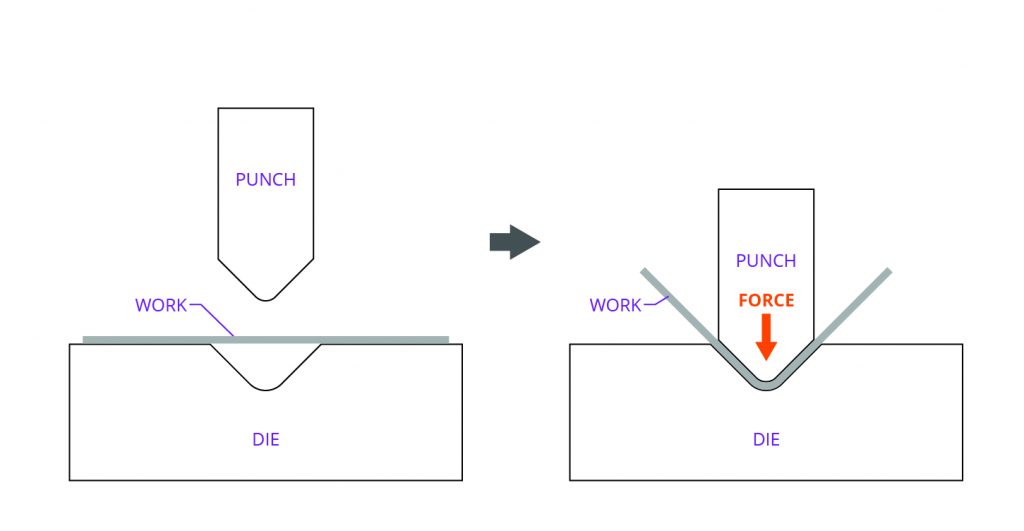

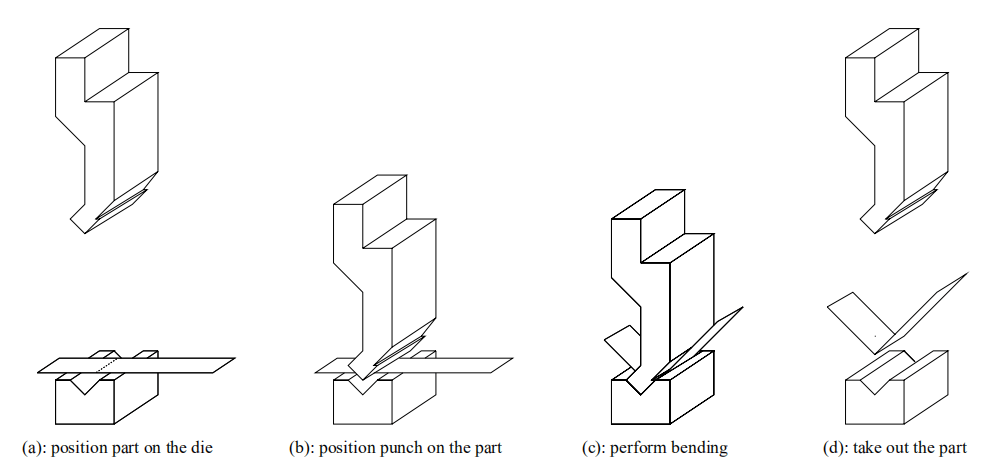

Finally punching is a sheet metal forming process that involves the use of a punch and die set to create holes in sheet metal. Capping presses form caps from rolls of aluminium foil at up to 660 per minute. The sheet metal is placed between the punch and die. Home metal fabricating tips facts punching process.

A stamping press is a machine press used to shape or cut metal by deforming it with a die. A punch press is used to form holes. Generally used for thin sheet metal processing. A pure punching machine with an automatic conveyor system can process sheet sizes of 1250 x 2500 mm.

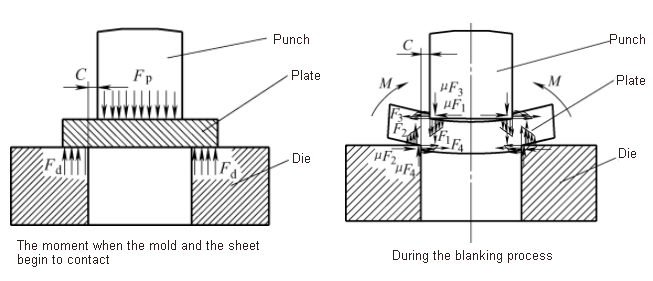

Next the punch presses down and through the sheet metal to create a hole. Characteristics of the punching process include. When the plate is thick such as 2 0 2 5mm etc we can directly tap the wire without turning over. The punch often passes through the work into a die a scrap slug from the hole is deposited into.

Punching is a cutting process in which material is removed from a piece of sheet metal by applying a great enough shearing force punching is very similar to blanking except that the removed material called the slug is scrap and leaves behind the desired internal feature in the sheet such as a hole or slot. In metal construction and the building industry use punching to produce profiles in sheet metal.