Thermo Forming Aluminum Sheet Shaping

This usually has a backing of paperboard or a lidding seal of aluminum foil or plastic.

Thermo forming aluminum sheet shaping. Follow along as i demonstrate how you can begin shaping metal with hand tools only. Twenty four hours at 176 f 80 c dries most sheets. It is known to be perfectly suited for prototyping and small series. Microstructure products means products that have structures in the micrometre range and have their technical function provided by the shape of the microstructure 1.

The single point incremental forming process is an emerging process which presents an alternative to the conventional sheet metal forming processes like hydroforming and drawing. To reduce the length of the forming cycle pre dry the sheet in a spare oven and transfer it directly into the forming oven at 176 f 80 c after the drying period. This fire protection system is available for retrofit on all brown ovens and can also be retrofit to many other brands of single station cut sheet machinery. Microthermoforming is the abbreviation for microscopic or microscale thermoforming or more precisely for thermoforming of microproducts or microstructure products.

The primary component of a blister pack is a cavity or pocket made from a formable web usually a thermoformed plastic. In the event excessive sheet sag occurs during thermoforming an independent safety sag eye automatically shuts the oven down activates the curtain and an air jet cools the sheet. By doing so the sheet can be bent or stretched into a variety of complex shapes. Thermoforming 2 in turn means shaping of heated and.

Pressure forming in addition to utilizing a vacuum underneath the sheet air pressure typically 50 psi but up to 100 psi is applied on the back side of the sheet to help force it onto the mold. How can you go about shaping metal with hand tools alone. The sheet is heated in an oven to a temperature where it can be stretched into or onto a mold and cooled to a finished shape. Blister packs are useful for protecting products against external factors such as humidity and contamination for extended.

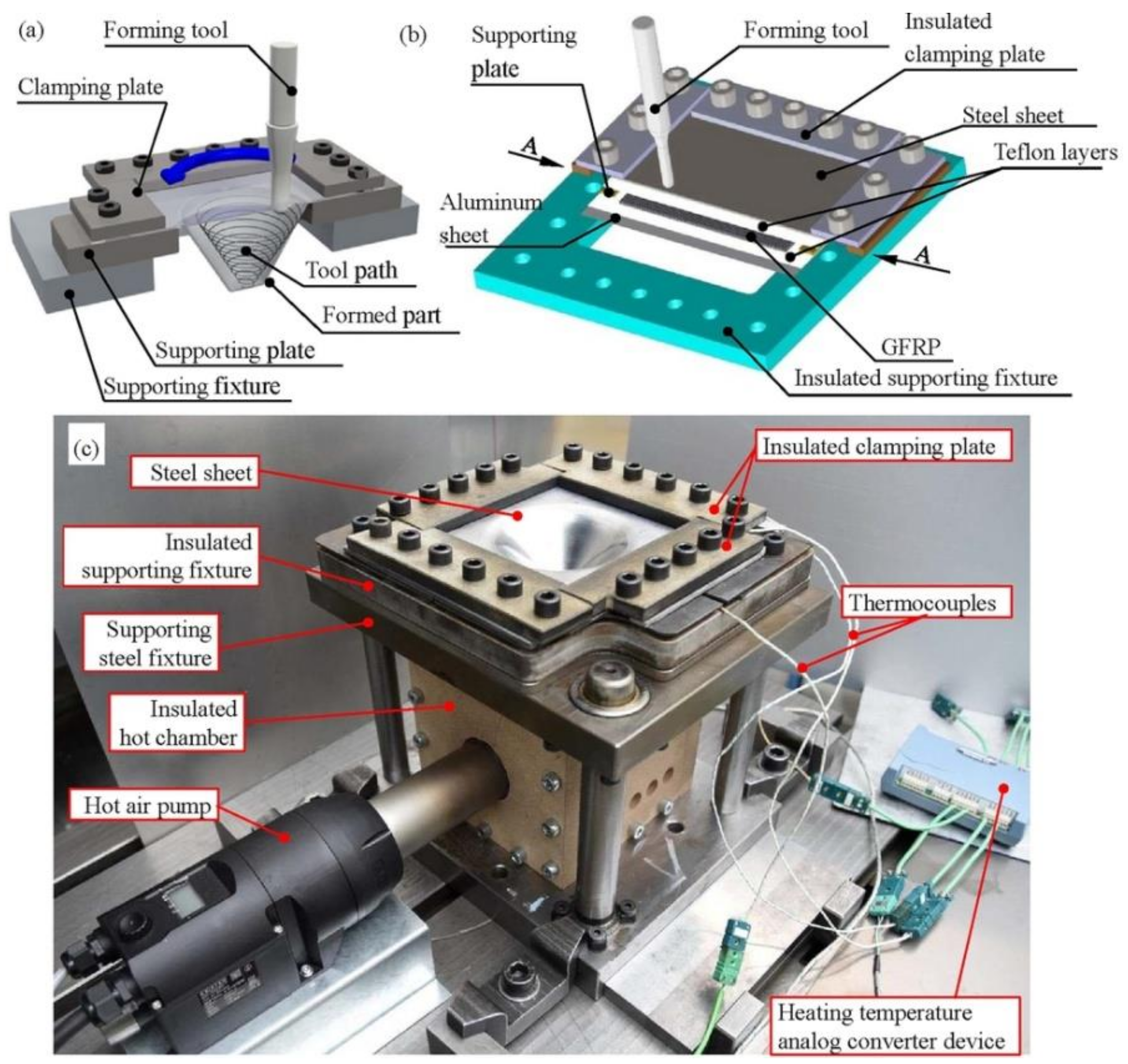

Sheet metal forming processes are those in which force is applied to a piece of sheet metal to modify its geometry rather than remove any material. The applied force stresses the metal beyond its yield strength causing the material to plastically deform but not to fail. It is important to provide sufficient clamping of the sheet during the forming process. The sheet or film when referring to thinner gauges and certain material types is heated in an oven to a high enough temperature that permits it to be.

For example the incremental forming process offers the possibility of manufacturing medical prosthesis or implants specific to each patient which. Thermo forming is a manufacturing process whereby a plastic sheet is heated to a pliable forming temperature then formed to a specific shape in a mold and trimmed to create a usable product.