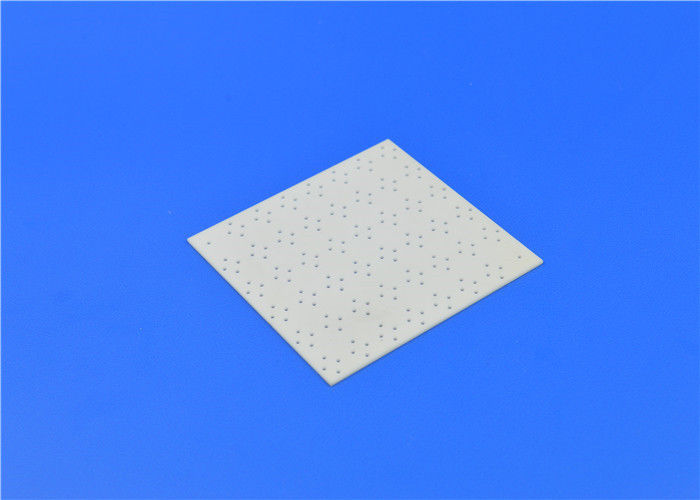

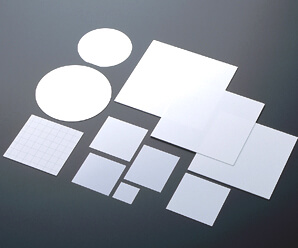

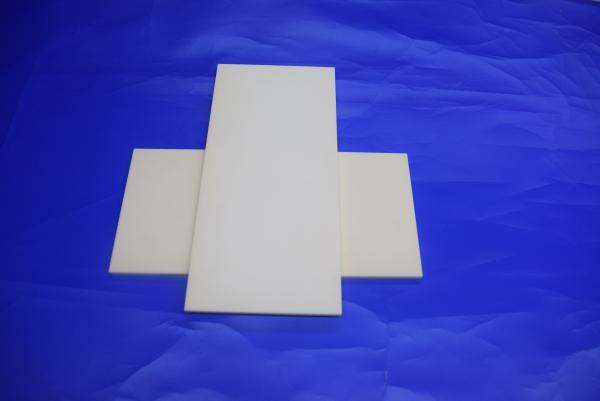

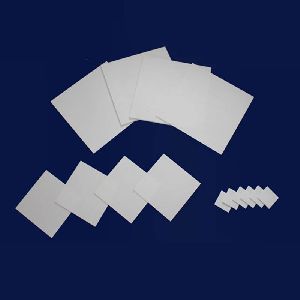

Thin Alumina Ceramic Plates

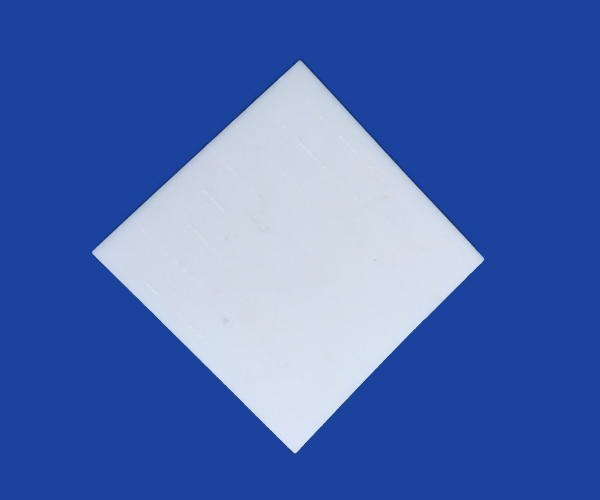

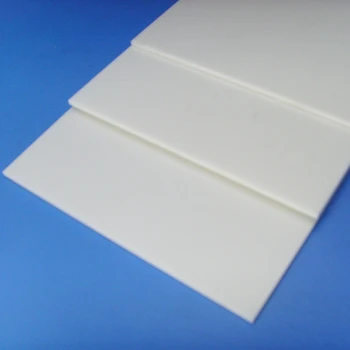

Alumina plate description alumina plates can withstand high temperature and maintain high strength and hardness alumina plates also have superb performances in electrical insulation high chemical resistance and low thermal expansion.

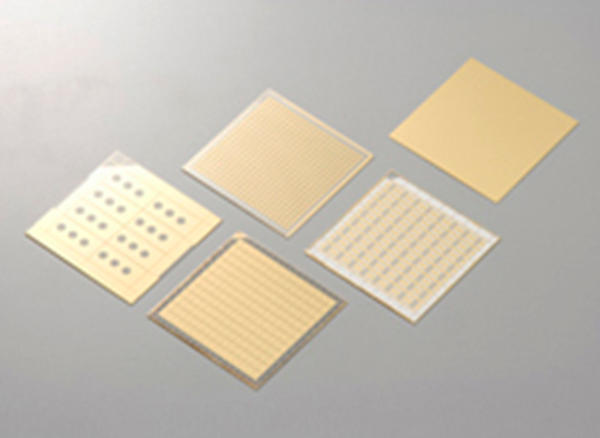

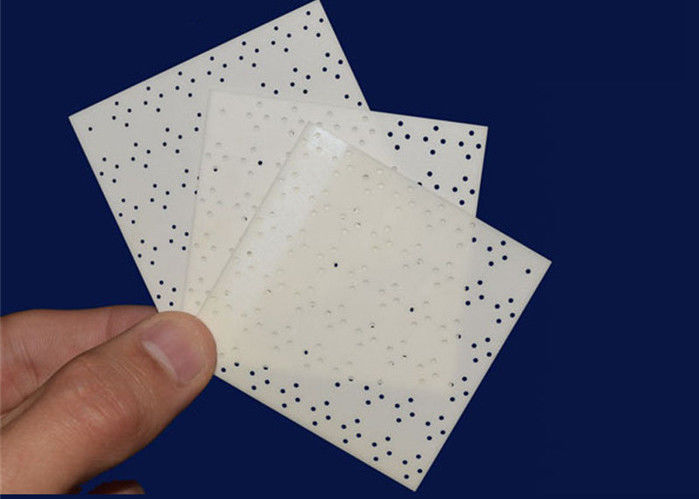

Thin alumina ceramic plates. High quality very thin alumina ceramic plate substrate sheets for medical device from china china s leading alumina ceramic substrate product with strict quality control alumina ceramic sheet factories producing high quality alumina ceramic sheet products. Coorstek controls surface finish grain size and surface imperfections to enhance fine line resolution spacing and yields in your thin film process. 2015 certified manufacturer specialized in research development manufacturing of ballistic helmets ballistic vests ballistic panels and stab resistant vests. Ceramic crucible leco 528 018 manufacturer of carbon sulfur crucible cs crucible for leco cs230.

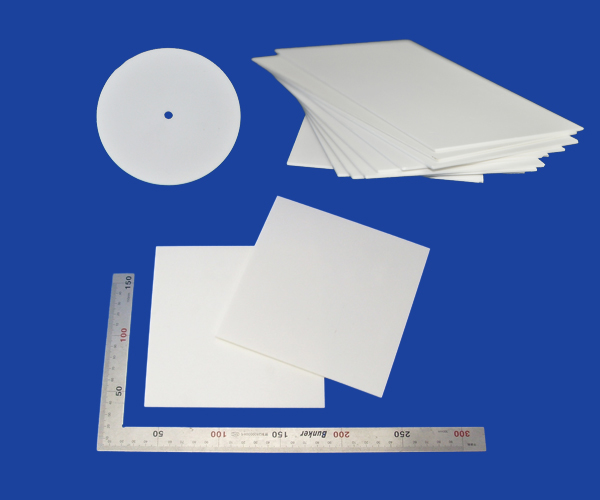

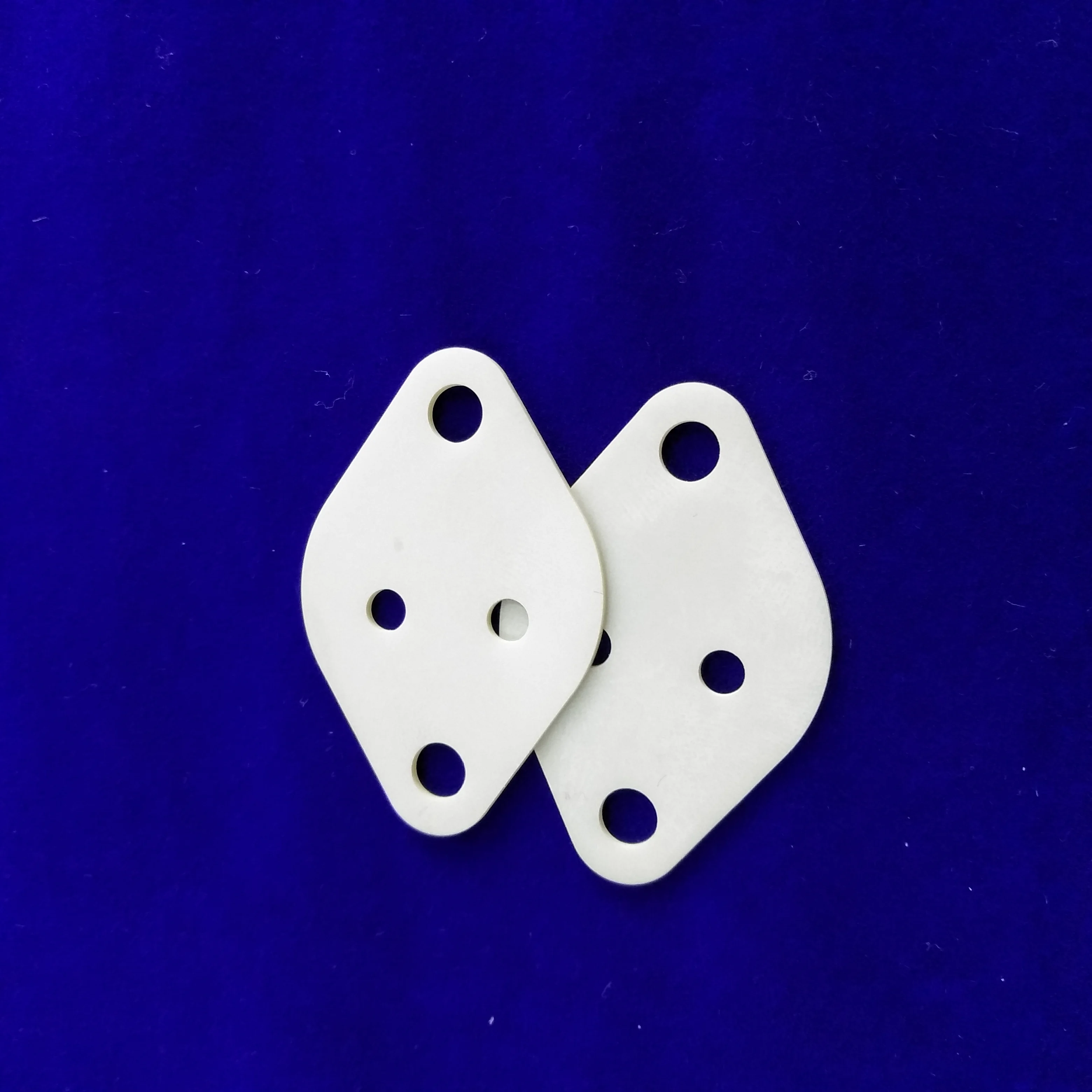

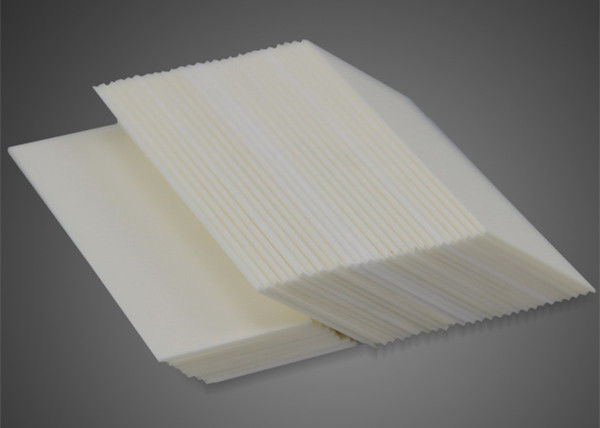

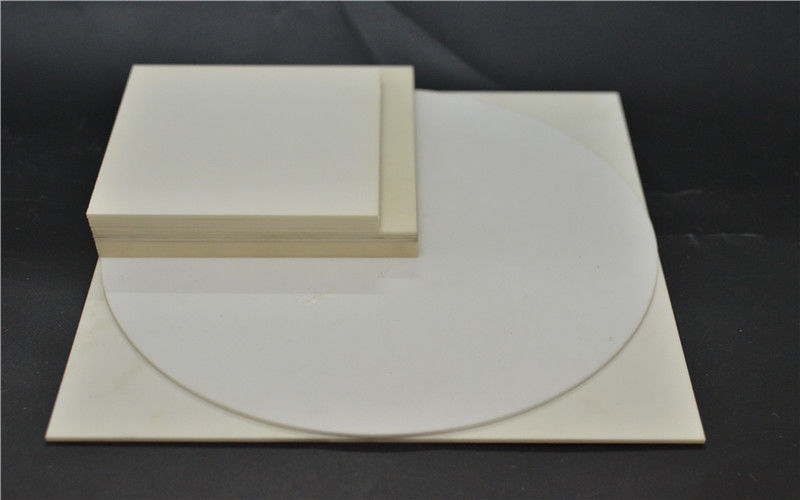

Higher purity alumina demonstrates enhanced wear and corrosion resistance creating a continuous scale of various alumina grades compositions and performance. Aluminas are used in both general use and specialized applications. Alumina ceramic plates thin alumina ceramic sheet alumina ceramic substrate features. We have various sizes of semi finished shapes in stock and are able to conduct custom manufacturing for all kinds of alumina components.

4 long time warranty. Carbon sulfur crucibles 528 018 eltra 90150 alpha ar3818 ceramic crucible for carbon sulfur analyzer. Alumina is a ceramic material with high thermal conductivity compressive strength and thermal shock resistance. Alumina ceramics are commonly subdivided according to their alumina content ranging from 80 to more than 99.

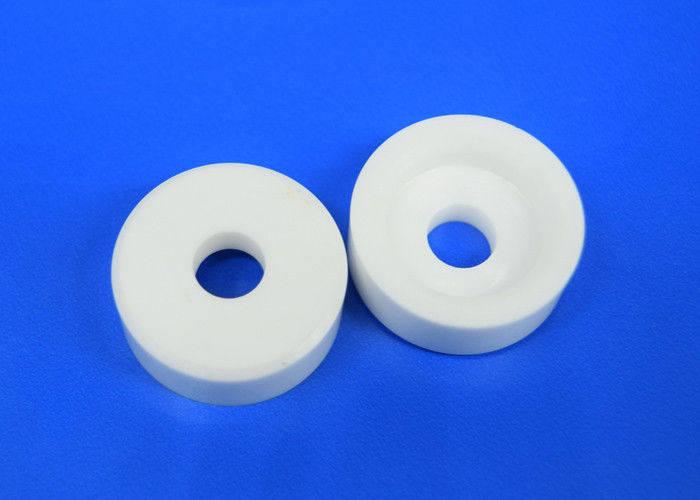

Militech alumina ceramic pe panel s nij iv 0101 06 stress testing video by bmt australia click here and add our store to your favorites you are buying from an iso 9001. Alumina plate is made of aluminum oxide ceramics. For example molten metals cannot wet aluminum nitride ceramics. Various sizes available and we can customize as your requirement.

1 high hardness high strength high wear and chemical corrosion resistance low expansion coefficient. Aluminum nitride and ultrapure alumina 99 can be used both in protective gas atmospheres and reduction atmospheres. Coorstek substrates are available in as fired and finished form and in both. Alumina is an optimal material for most thin film ceramic substrate applications.

It also has a low thermal expansion making it a suitable material for furnace use in the crucible tube and thermocouple sheath form.