Spacing For Purlins Forfiber Glass Roof Panels

The wider the roofing panels the greater spacing distance you should put.

Spacing for purlins forfiber glass roof panels. R panel install 11 21 11 metal roofing materials metal the r panel metal roofing panel is an industry leader purlins decks and fasteners must be designed to resist all loads imposed on the panel ng winds 2 1 3 4 5 install metal directly to wood frame use maximum 5 purlin spacing install metal not recommended for heated. An engineer will use a load chart in order to determine the spacing between metal purlins. The metal roof purlins spacing must be done correctly within narrow tolerances. There is a chance of damaging roofing sheets if you are failed to do so.

Beginning at the outside edge of your roof place each panel directly onto the purlins that are attached to the roof trusses. When looking at the ends of the rails the purlins shapes look like the letter c or the letter z the eave purlin marks the first purlin at the wall connection. Fyi we run purlins on 3 5 feet on center depending on size of purlin. These roofs are commonly problematic because the rib spacing is typically inconsistent thus not permitting a standard factory notched hugger sub purlin to be used.

To install corrugated roofing start by cutting your panels to length with an angle grinder. Screw line spacing for metal roofing over metal purlins. Without a set of blueprints with a pe s seal you have no option but to follow the inspectors gig. A metal roof must also allow for some overlap on each side of the panels which will reduce the effective width of the panel.

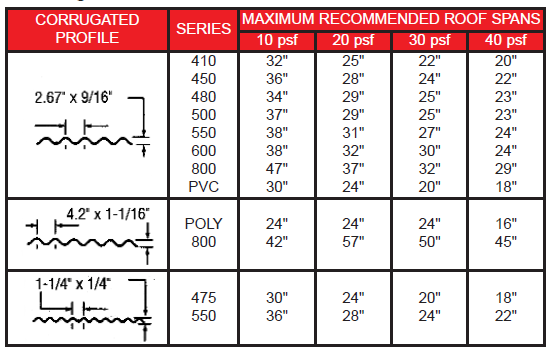

There are countless old corrugated roofs out there with 2 5 2 67 2 75 and 4 25 rib spacing as well as other ribbed type panels such as the 7 2 industrial rib roof panel. Table is based on section properties or actual load tests available upon request. On a standard load most designs call for purlin placement at five foot intervals. The purpose of the purlins is to provide a solid foundation for the metal roofing panels and trim to be screwed to.

In heavy snow areas 500 series or greater panels are recommended and closer spacing of purlins should be considered. While panels may not fail under heavy snow loads strain at fastening points can cause slight cracking. This will depend upon the type of panel that is used and the thickness of the steel. Wider panels allow for greater spacing between rafters.

Purlin spacing is dependent on profile of the metal and gauge plus snow and wind load plus what the rafters are designed to carry. To determine how far apart to set rafters measure the width of the metal panel and then the width of the first hill and valley of the panel. However engineering determines the optimal spacing between the purlins. Once the purlin spacing is determined then the metal roofing panels are typically attached to every line of purlins.